Small Cotton Seed Oil Production Line

What Is Cottonseed Oil?

Cottonseed oil is a cooking oil made from the seeds of the cotton plant. It belongs in the same category as canola oil, soybean oil and safflower oil, as it’s really an inflammatory “vegetable” oil that’s processed and can easily oxidize when exposed to high heat, light and air.

Cottonseed oil is refined in order to remove gossypol, a naturally occurring toxin in the seed’s oil that works to protect the plant from insects. If consumed, this natural pesticide may be toxic, so it’s always removed from the seeds that are used to make cooking oil or flour.

You’ll find hydrogenated cottonseed oil on the ingredient list in many processed and packaged foods. It’s used in salad dressings, baked goods, cereals and more. (Read More about Sunflower Seed Oil Making>>)

Therefore, many investors have begun to consider the cottonseed oil processing business and want to open their own oil manufacturing plant to produce cottonseed oil. But what they worry about is that with the gradual rise of large edible oil processing plants, can small cottonseed oil mill plants still make money? Now, as an excellent supplier and manufacturer in the field of edible oil processing, We will provide investors who are interested in cottonseed oil processing with ideas for building factories and help you start your business plan at a lower cost.

How To Establish Small Cotton Seed Oil Mill Plant?

If you are going to start an oil mill plant for business purposes, establishing a small cotton seed oil mill plant is rather a good choice. But how to establish a small-scale oil mill plant for cotton seed oil, and how to ensure the efficiency and profits of your cotton seed oil production? Check out below considerations to establish an efficient small cotton seed oil mill with ease.

- Do complete market research

It is virtually important to have a complete market research about cotton seed oil. But, for cotton seed oil, the global demand for cotton seed oil is far larger than the global supply of cotton seed oil. Therefore, it is absolutely profitable to establish a complete oil processing plant for cotton seed oil.

- Make a comprehensive business plan

You are going to have a clear idea about your sources, including available capitals, factory lands, effective sale channels, and more. Knowing what you have and what you can offer will ensure a smooth process to set up your own oil mill plant.

- Find a reliable supplier for your cottonseed oil mill plant

There are many ways to get information about different cotton seed oil processing machinery manufacturer.We are dedicated to designing, manufacturing and installing highly efficient vegetable oil mill plant projects for our customers. We offer A~Z solutions for oil processing plant, including cotton seed, castor seed, sunflower seed, soybean, groundnut, and more.

- Continue to learn the knowledge of cottonseed oil plant operation

Last, it is necessary to learn more about how to operate your oil mill plant and grasp more marketing skills to expand cotton seed oil sales.

To establish a cottonseed oil processing plant project, you must choose the appropriate cottonseed oil processing equipment according to your daily oil output in order to purchase cost-effective cottonseed oil mill machines. If you want to know the detailed configuration and quotation of cottonseed oil manufacturing equipment, you can click the button below to consult QIE.(Read more:1~20tpd small solvent cottonseed oil production plant>>)

Cotton Seed Oil Processing Process

If you are going to establish a cotton seed oil mill plant, no matter how big it is, knowing the detailed process of cotton seed oil making is useful for normal and long-term operation. The main process of cotton seed oil processing are seed pretreatment, oil pressing and oil refining.

Cotton Seed Pretreatment For Oil Pressing

Before loading into cotton seed oil press machine, the cotton seed should be processed by a series machine to ensure high oil output, including delinting, frying, impurities removal, grinding, cotton seed oil cake making, etc. The machine involved in this process may have cleaning sieve, cooker, seed delinting machine, ect.

Cotton Seed Oil Pressing

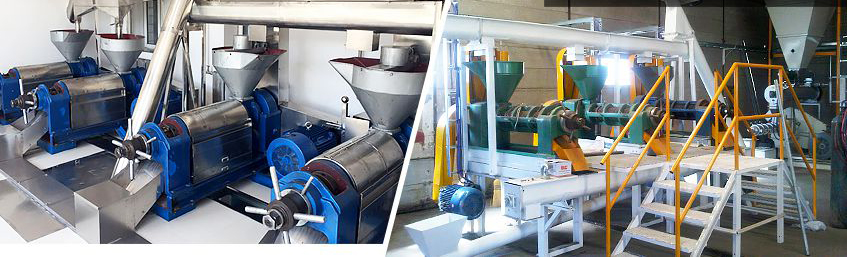

For small cotton seed oil mill plant, screw oil mill press equipment is the most suitable for machinery because of its high efficiency and low investment cost. Cotton seed oil press is the screw oil expeller that can be used for most oil oil-bearing seeds to extract oil out. Compared to other oil manufacturing unit, the cotton seed oil machine has many unmatchable advantages.

Screw Oil Mill Press Equipment

- It can easily designed with heating system and oil cake meshing device for highest oil output

- It is designed with stainless steel oil cover and oil

- It is small in size, but efficient in operation, so it requires less land for your cotton seed oil mill, save investment cost, at the same time, ensure efficient cotton seed oil production

- It is also suitable for other plant seeds, so which also provides you more opportunities to expand you oil making business

- User-friendly operation and less machine maintenances for worries-free and continuous oil production

Cotton Seed Oil Refining Machine

Although cotton seed oil is also the main cooking oils, the crude cotton seed oil contains cotton phenol (about 1%), colloidal and waxy substances (the amount is based on the content of oil in cotton seed). Therefore, the quality of crude cotton seed oil is poor and is not suitable for eating or cooking directly. Oil refining process in cotton seed oil processing plant is used to refine crude cotton seed oil for high quality oil. The complicated process involved in cotton seed oil refining mainly includes: filtration of crude oil, degumming, deacidifying, decolorizing, deodorizing. We have rich experiences in cotton seed oil refining, we have established many refinery projects for cotton seed oil, ranging from 1TPD ~ 30TPD, especially in Afghanistan.

If you still have no ideas about how to establish a small cotton seed oil mill plant, please contact us directly. We have many hands-on experiences about cotton seed oil processing, both in oil pressing and oil refining. We can not only offer you the most suitable cotton seed oil processing machinery to help you build up a customized efficient cotton seed oil mil plant,but also guarante you the most competitive price to minimize the investment cost.

Business Plan of Small Cotton Seeds Oil Mill

Cotton seeds are one of the top four genetically modified crops grown in the world, besides soy, corn and canola. They have similar structures as sunflower seeds. There is a hard outer null with an oil-bearing kernel inside it. Cotton seeds are one of the top four genetically modified crops grown in the world, besides soy, corn and canola. They have similar structures as sunflower seeds. There is a hard outer null with an oil-bearing kernel inside it. The oil is extracted from the seeds or kernel of varieties of species of cotton plants.

Cottonseed Oil offers a unique business opportunity. By 2028, the global cottonseed market will reach a value of over 5 billion dollars. It is foretasted to grow by 3.2% over the next few years. This increased demand for cottonseed oil is mainly due to the food processing and snack food industry.

Cottonseed oils are used to judge the standard of other oils. This is due to its natural and mild flavors and tastes. this is the standard by which other oils are measured. Brominated Oils can also be produced for cottonseed oils, these have a high calorific content suitable for people on specific diets. Cottonseed oils are suitable for cooking and frying; this makes it a popular option for there snack food manufacturers, bakers and confectioners, as well as other food manufacturers. These companies are always looking for new and healthier alternatives. It is also a viable substitute for the soap making industry. This versatile oil is a great investment opportunity.

Firstly, you will need a large piece of land. This is for you to have ample space for your machinery and office. You will also need to have capital. At the start of your business, you will need to equip your office with the necessary oil processing equipment. It is also important that you source for good seeds around your intended business space. The quality of your oil will depend on the raw material that you use. It would help to reduce transport cost too. Don't hesitat to tell us your needs and let us help you make the most suitable plan!