Sunflower Oil Production Line

Sunflower Oil Production Line Introduction

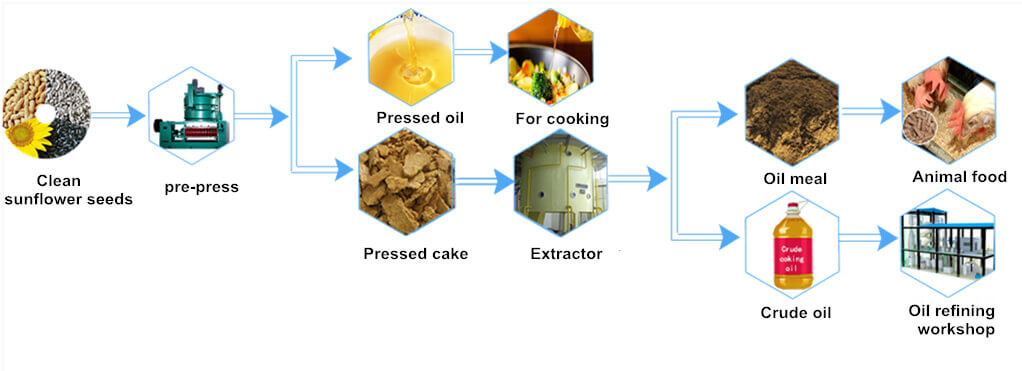

Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and is beneficial to protect cardiovascular health. Besides the unsaturated fatty acids, sunflower oil also contains vitamins E, folic acid, iron, potassium, zinc and other essential nutrients.

Currently, the sunflower oil sold on the market is mostly produced by de-shelled pre-squeezing and leaching process. De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g. However, by squeezing-leaching seeds with shell, every 100g sunflower oil only contains 41.62mg vitamin E. What's more, there is no contact with alkane in the process of the un-shelled pressing-leaching process, which avoids the formation of trans fatty acids.

Sunflower Seed Oil Processing Steps Flows

Seeds Screening

Select clean sunflower seeds with an oil content of 30~50%, and remove impurities (sediment, stone, iron filings, etc.) contained in the seeds by cleaning sieve and magnetic separator.

Shelling & Crushing

Sunflower seeds should be pressed after shucking, which can improve production capacity and oil quality. After the sunflower seeds are screened, they are shelled in a sheller. Then through the grinder crush into a certain granularity of sunflower seed particles.

Rolling & Steaming

Roller embryo is the grinding of sunflower oil seeds into a certain thickness of the embryo, its role is to destroy the cell tissue so that the oil is easily extracted.

After pre-extrusion, the structure of the extruded cake is loose but not crushed, which is conducive to solvent penetration for the extraction process. The quality and economic benefits of the oil extracted by the pre-pressing and extraction process are better than that of the oil extracted by single pressing or single extraction.

Crude oil refining

The steps of sunflower oil refining are basically the same as those of other vegetable oils, including degumming, alkali refining, decolorization, deodorization, and dewaxing. The refined product is not only light in color, but also has high nutritional value and good taste. It is a good edible oil.

Equipment

Alkali refining pot, degumming machine, decoloration pot, deodorization pot, crystallizing tank, dewaxing press filter, oil pumps and other parts.

Process features

(1.) Degumming: when the intermittent process is used, refining consists of heating the oil to between 40 and 85℃, by adding the concentration of 85% industrial phosphoric acid which accounts for 0.1%~0.2% of oil content to the crude oil, the mixture should be stirred for 0.5 h for degumming;

(2.) Alkali refining: then the alkali is added to remove the acid by adding the lye. The excess alkali content is 0. 2%~0. 4% of the oil weight;

(3.) Washing: the oil is washed under the absolute pressure of 8kPa (vacuum degree is above 700mmHg) at the temperature of 90~95℃, and then is vacuum dehydrated by dryer;

(4.) Decolorization: the active white soil which accounts for 4%~6% of the oil-heavy is added to adsorb pigments for decolorization, then the waste white soil is filtered;

(5.) Deodorization: the decolorized oil needs to be placed under vacuum pressure at the temperature of 230~250℃, and is distilled by passing 0.1~0.2MPa direct water vapor for more than 4h, then through cooling and fine filtrating.

(6.) Dewaxing: the deodorized sunflower oil also contains a small amount of wax, which is pumped into a pre-cooled crystallization tank and cooled at a certain cooling rate in 8 hours, in order to speed up the reaction and uniform cooling, appropriate mixing is necessary, and stirring speed can be 10~15r/min. After the oil is cooled and crystallized to a certain temperature, stirring is stopped and the crystal keeping time is maintained for 12 hours in the crystallization tank. After that, the oil and wax are separated by press filter, using compressed air. The discharged liquid oil is the finished sunflower oil, which can meet the standard of high-grade cooking oils.

Features of Sunflower Oil Production Line

Characteristics of the oil pressing and extracting

- Compared with other oil extraction methods, the oil pre-pressing has the advantages of simple process, less supporting equipment, strong adaptability to oil varieties, flexible production, good oil quality, light color, and pure flavor.

- However, the cake has a high residual oil content after squeezing, resulting in high power consumption and easy loss of parts. This method can be used to extract oil from peanuts, rapeseeds, sunflower seeds and other seeds or nuts. At the same time, the pre-pressed cake is sent to the leaching workshop to further extract the residual oil in the cake to achieve a better oil-making effect.

Characteristics of the oil refining process

- For the refining part, we provide a full set of equipment for batch refining process, semi-continuous refining process, and full continuous refining process(more than 50 tons per day).

- Batch refining process has a daily capacity of 1~30 tons of sunflower oil. It has features of less investment, convenient operation and small footprint.

- Semi-continuous refining process has a daily capacity of 30~50 tons of seed oil. It can be used for different types of oil refining, and it has advantages of low power consumption, better refining rate than batch-type and traditional semi-continuous processes.

- Full continuous refining process has a production capacity of more than 50 tons per day. With characteristics of high refining yield and low consumption of auxiliary materials, full continuous refining process can meet the requirements of deep processing of products. The process requires continuous operation, which is suitable for larger scale production of the continuous production enterprises.

Sunflower Seed Oil Application

Sunflower oil is a high-quality edible oil known as nutritive oil, which has become the preferred oil for consumers and chefs. And the worldwide consumption of sunflower oil ranks third in all vegetable oils. It is generally used for cooking, for example, it is used to make margarine, mayonnaise, salad dressing and salad oil. The artificial cream obtained with sunflower oil has excellent taste and high unsaturated fatty acid content. In the food industry, sunflower oil is also used to make fried fast food, such as potato chips and corn chips. The sunflower oil cake which obtained after squeezing contains 30%~36% of protein and 8%~11% of fat. In addition to feed, oil cake can also be used to produce monosodium glutamate and soy sauce. The protein in the sunflower kernels is composed of reasonable amino acids and can be used to make edible protein powder. The sunflower shell can be used as a fuel to generate steam and electricity, as well as animal feed and furfural production.