Soybean Oil Production Line

A soybean oil production line extracts oil from soybeans through physical and chemical processes and refines it into edible oil. As global demand for vegetable oil grows (especially in Asian and North American markets), investing in soybean oil processing plants has become an industry with stable returns.

A complete soybean oil production line mainly includes raw material pretreatment, pressing/extraction, refining, and bottling. It can flexibly design production capacity according to investment scale, from small-scale (1-10 tons per day) to large-scale (over 100 tons per day).

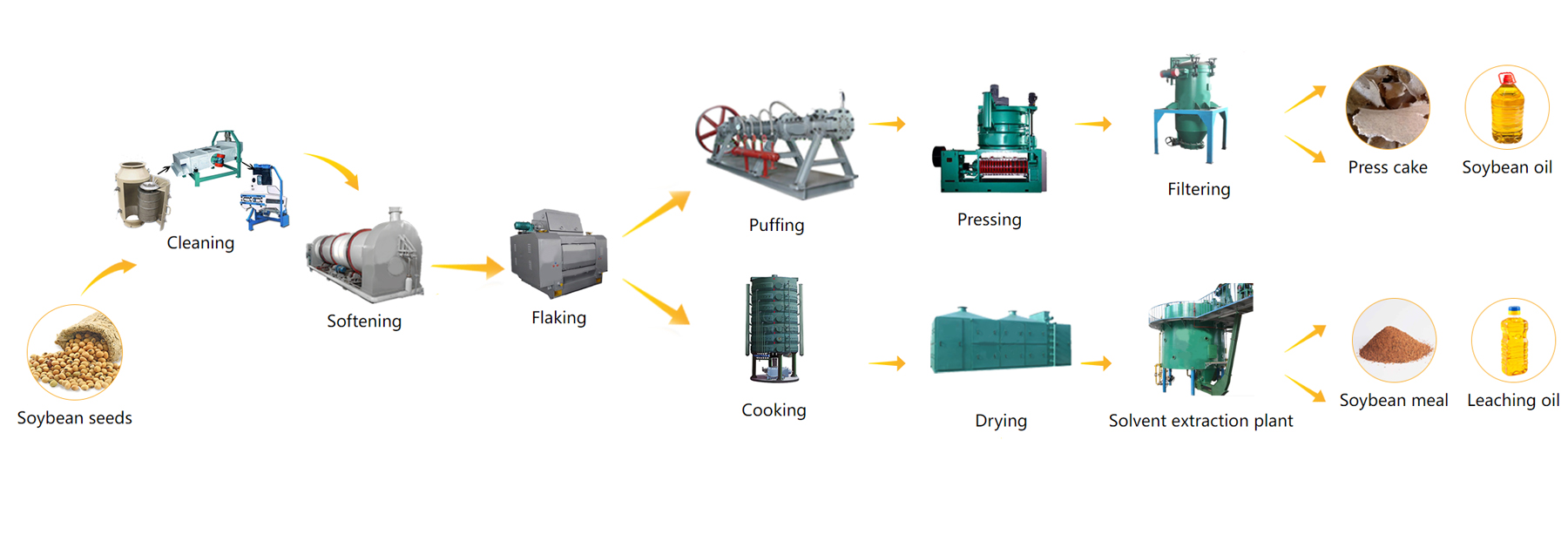

The whole set soybean oil production line is composed of soybean pretreatment section, soybean oil solvent section and soybean oil refinery section.

Soybean Pretreatment Process

Pretreatment directly affects soybean oil yield and quality, accounting for about 25-30% of the total processing energy consumption. This stage mainly includes cleaning, crushing, softening, flaking, and extruding.

Soybean Cleaning Equipment

High efficiency vibrating screen is adopted here to remove the impurities, so as to effectively achieve the cleaning effect, ensure good operating environment and stability of production, and simultaneously improve the product quality. Suction-type specific gravity stoner is used for removing the mud and stones which have the same size as soybean. The unpowered magnetic selector is applied for removing the iron, and also dust remover is equipped in this process.

Soybean Crushing

In order to achieve the good softening and flaking effect, the soybean needs to be crushed into 4-6 pieces to ensure the uniform granularity. Therefore, when softening, the moisture is uniform and thoroughly. And the flake piece is thin but strong when flaking. The common cracking equipment is roll crusher, hammer crusher and disc huller.

Soybean Softening Machine

The horizontal softening machine is adopted here to heat the soybean to 50-70℃. Therefore, the plasticity of soybean is increased through adjusting the moisture and temperature, creating good operation condition for flaking and cooking. The softening process can not only make the flake become thin, uniform and tough, but reduce the nonhydratable phospholipids content in crude oil, which is convenient for the dephosphorization and physical refining of salad oil.

Soybean Flaking

The cytoderm of soybean is destroyed in this process, meanwhile, the crushed soybean with a certain granularity is made into thin slices with the thickness of 0.3mm, which aims at extracting the maximum oil in the shortest time. Thereby, the extraction speed and rate are increased, and the residual oil in soybean meals is <1%.

Drying

Generally, the flake made from flaking roll has the water content of 12%. However, the optimum moisture for leaching process is 9%, so an effective drying is necessary to achieve the best leaching moisture.

Generally, the flake made from flaking roll has the water content of 12%. However, the optimum moisture for leaching process is 9%, so an effective drying is necessary to achieve the best leaching moisture.

Strategies and Solutions for Optimizing Soybean Oil Pretreatment

Optimizing the soybean oil pretreatment process is essential for maximizing oil yield while maintaining cost-effectiveness. By leveraging advanced technologies and adopting best practices, manufacturers can significantly improve their production process.

Adapting the Process to Different Raw Materials

Soybean quality can vary depending on the region and season. Adjusting the pretreatment process to suit different raw materials can help achieve consistent oil yields. For example, soybeans with higher moisture content may require additional conditioning to optimize extraction.

Incorporating Advanced Technologies

Technologies such as Near-Infrared Reflectance (NIR) sensors and MES (Manufacturing Execution Systems) can be integrated into the pretreatment process. These technologies allow for real-time monitoring and optimization, leading to improved process control and reduced waste.

Enhancing Yield and Quality

By optimizing temperature and moisture during conditioning, manufacturers can ensure that the soybeans retain optimal oil content. Additionally, adopting modern flaking mills and presses can increase oil yield and improve the quality of the final product.

The optimization of soybean oil pretreatment leads to higher oil extraction rates, reduced energy consumption, and lower overall costs. By implementing these strategies, manufacturers can stay competitive in the market and maximize their return on investment.

Soybean Oil Solvent Section

There are two methods of soybean oil production, one is mechanical way, which is a traditional method that use screw press machine to squeeze oil out from seeds and kernels; the other way is chemical method that extract oil with solvents. Both two oil production methods have advantages and disadvantages. The previous one is natural and healthy but the oil yield is much lower, however, oil yield of the solvent extraction method is much more higher. You can choose one according to the capacity and your oil making needs, or you can use the two together.

Soybean Oil Pressing Process

The pressing method is the traditional method of soybean oil extraction. It involves the use of pressing plants, such as a screw press or oil press, to physically force the oil out of soybean seeds. This method is more suitable for small-scale operations and requires minimal chemical usage. However, it may result in lower oil yields compared to solvent extraction method.

How to Select Suitable Soybean Oil Pressing Mill for Business?

|

|

|

| Screw Oil Press | Integrated Screw Oil Press | Large Scale Oil Press Machine |

1. Matching equipment selection: the basis for quality pressed soybean oil production

Different production and processes have different requirements for soybean extraction equipment. For example, some equipment may be better suited to specific pressing temperatures and pressures. Ensure that the equipment you select meets the requirements of your production process in order to obtain high quality soybean oil.

2. Matching production size: increasing productivity

Different sizes of soybean oil pressing equipment are suitable for different production needs. Fully understand the scale of production and market demand to determine the capacity of the required equipment. Selecting equipment that matches the production scale helps to improve efficiency.

Soybean Oil Solvent Extracting Process

The extracting method uses the principle of mutual dissolution of solvent and oil to produce soybean oil. Oilseeds with an oil content of about 20% are more suitable for extracting production and processing. For oilseeds with high oil content, we can first press the oilseeds with a pre-press machine, so that the oil content in the oilseed cake reaches about 15%, and then use the extraction methods, so that the leaching effect is better, and the oil yield is also more.

The production of soybean oil by extraction methods requires pretreatment of oilseed raw materials, including cleaning, steaming, frying, and puffing. Different raw materials have different pretreatment steps. After pretreatment, we can use solvent for extracting production. After extracting, we get gross cooking oil and a cake meal. Among them, the residual oil rate in the cake is less than 1%, which can be used as a raw material for animal feed processing for sale. Crude soybean oil needs to be refined before it can be sold or eaten.

Which Soybean Oil Processing Method Is Better: Pressing or Solvent Extraction?

Are you planning to build a soybean oil processing plant but wondering whether to choose pressing or solvent extraction?

Pressing

Using a soybean oil press machine, this process relies on physical pressing, producing healthy, additive-free oil with rich nutrients, natural flavor, and aroma.

However, the oil yield is relatively low and the price is higher. This method is ideal for small to medium-sized cooking oil mill plants, where production lines can be flexibly customized based on capacity, budget, and available space.

Solvent Extraction

Through a soybean oil solvent extraction line, the oil yield is significantly higher, oil purity is greater, and costs are more competitive. The by-product, soybean meal, is widely used in animal feed and protein processing industries.

With higher efficiency and automation, this process is commonly applied in large-scale cooking oil production plants and cooking oil processing plants, helping to reduce both production and labor costs.

Both methods have distinct advantages. Choosing the right one depends on your market positioning, budget scale, and production requirements.

As a trusted global cooking oil manufacturing plant supplier, QIE GROUP delivers complete cooking oil production line solutions, including Customized cooking oil equipment solutions, Cooking oil equipment automation, and services as a fully automatic cooking oil refinery supplier.

Our advanced technology helps clients achieve higher efficiency, optimized refining, and improved oil quality.

Features of Soybean Oil Solvent Extracting Technology

- High oil yield. Residual oil in soybean meals is <1%.

- The soybean meal is of good quality.

- Low processing cost and low labor strength.

Soybean Oil Extracting Device Classification

- Immersion Extraction: pot groups extractor, U-type ball extractor, and Y-type extractor

- Percolation Extraction: screen belt type solvent extractor

- Combined Extraction: rotocel extractor, loop type extractor

Main Process Of Soybean Oil Solvent Extraction Process:

Soybean Pretreatment --->Extruding --->Solvent Extraction --->Crude Soybean Oil

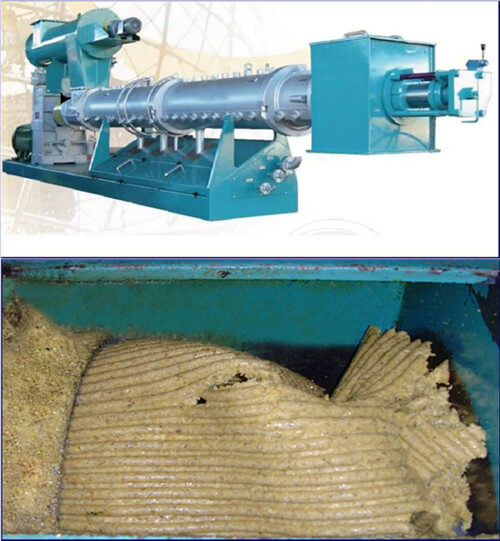

Soybean Extruding Process

Soybean extruding is the process of using extrusion equipment to break through the crushed, rolled soybean into porous, expanded granular material. Extrusion is a kind of high temperature and short time processing. At present, the commonly used soybean extruding machine is low moisture single-screw extruder, and the material is extruded by heating, pressing, gluing and vacuum extrusion. Generally, extrusion temperature can reach 110~200℃, and the residence time in the extruder is for the l~3 minutes.

The soybean extruder machine is specifically designed for processing soybeans. It uses high temperature, high pressure, and mechanical cutting to create an extrusion effect.After extrusion, soybean cell walls are broken down, resulting in irregular granules. This improves oil extraction efficiency and animal digestion and absorption.This equipment is widely used in soybean oil extraction and feed production industries, significantly improving oil yield and feed utilization.

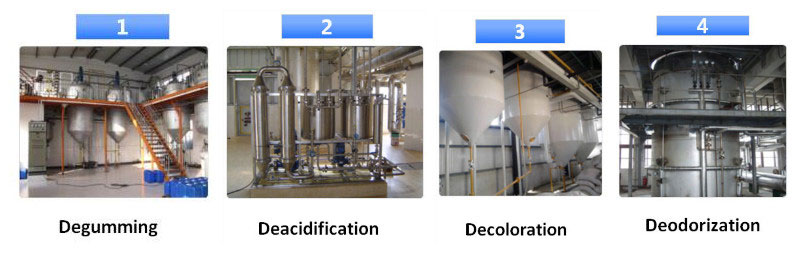

Soybean Oil Refining Process

Crude soybean oil is extracted through the mechanical pressing or solvent extraction method, which contains colloidal impurities, free fatty acids (FFA), pigments and odor substances and other impurities, affecting the storage and consumption of refined soybean oil. It is necessary to carry out further refining, in order to obtain the market value of soybean oil.

- The degumming process removes the colloidal impurities in the crude soybean oil, mainly phospholipids. Soybean oil and a certain proportion of phosphoric acid solution (or water) fully mixed, the reaction separation to remove phospholipids.

- The deacidification/alkalization process removes free fatty acids from soybean crude oil. Mix the soybean oil after degumming process with a certain proportion of lye to remove free fatty acid and phosphoric acid left in the previous process.

- Decolorization/bleaching process removes pigments and oxides that affect the color of soybean crude oil. The alkaline refinery oil and adsorbent white clay are mixed and reacted and then removed by a filter machine.

- The deodorization process removes the odor volatiles from soybean oil. Under the condition of reduced pressure and temperature, the decolorized soybean oil enters the deodorization equipment for deodorization reaction. After deodorization, the hot oil is cooled and fine filtered to get rbd soybean oil.

Setting up a soybean oil refinery plant is an ambitious but rewarding venture now. With the increasing demand for high-quality soybean oil, understanding the intricacies of the refining process and the necessary refining machines can significantly boost efficiency and profitability.

Soybean Oil Production Line Advantages

1. Perfect cleaning process: 99% impurities contained in the soybean can be removed in this process, thus reducing the mechanical wear and ensuring the soybean quality.

2. Accurate flaking technology: Cell tissue of soybean is destroyed. Therefore, the surface area is increased and the trip for oil flowing is shortened, which is beneficial to extract the oil and improve the cooking effect.

3. Environmental protection and energy-saving extracting system: Unique exhaust system, better absorption effect, sufficient energy saving design, multiple uses of heat energy, thereby, the steam consumption is saved.

Soybean and Soybean Oil

Soybean is valued for its high protein content (38-45%)) as well as its oil content (approximately 20%). Soybean oil is a vegetable oil extracted from the seeds of soybean, which has a mild nutty flavor and a better texture. It is one of the most widely consumed cooking oils, constituting about half of worldwide edible vegetable oil production. As a semi-drying oil, processed soybean oil is also used as a base for printing inks and oil paints. Thus soybean oil production line is installed worldwide.