Mini/Small Solvent Cotton Seed Oil Extraction Equipment

Cottonseed, the seed of cotton plant, is a main oil crop in the world. The oil content is up to 35~45% and the protein content is about 39%. Cottonseed oil contains a lot of essential fatty acids for human consumption. The refined cottonseed oil is popular edible oil around the world. (Read more: Edible Oil Manufacturing Plant Cost >>)

How To Deal With High Residual Oil In Cottonseed Meal/Oil Cake?

The widely applied oil extraction methods for cottonseed oil production: Mechanical Pressing & Solvent Extraction. Usually, the cost to setup cottonseed oil mill plant by solvent extraction is much higher than that of mechanical pressing. But, solvent extraction technology can extract oil more completely, the residual oil ratio is less than 1%. The cottonseed oil cake from cottonseed oil processing plant that is designed with mechanical pressing technology may contain 8%~13% oil.

Cost-effective Solutions for Cottonseed Oil Manufacturing Business

- Investors who are interested in cottonseed oil processing.

- Vegetable oil milling factories where produce bulk of oil cake every day.

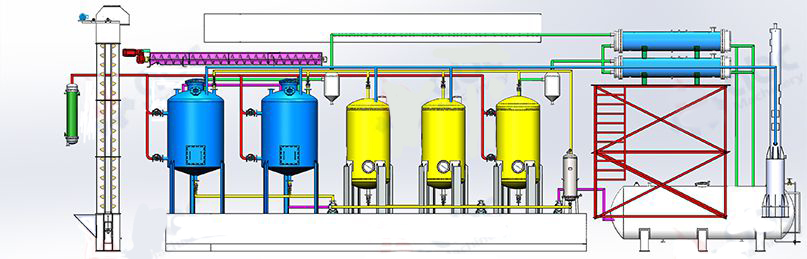

Mini/Small Cottonseed Oil Production Line Layout Design - Solvent Extraction

The new small cottonseed oil production plant adopts solvent extraction technology to obtain the cottonseed oil from cottonseed oil cake since solvent extraction is now the most efficient and advanced oil extraction method internationally. (Read more: Cottonseed Oil Mill Machinery Price >>)

- Capacity: 1~20 tons per day

- Main Equipment: Solvent Extraction Pot Group

- Applications: To extract oil from various oil cake and minimize the oil residual rate to 1%, like groundnut/peanut oil cake, rapeseed oil cake, sesame oil cake, soybean oil cake, etc..

Based on different requiremetns for cotton seed cake manufacturing, we provide two types of cottonseed oil production line. One is made from stainless steel, and the other is made from carbon steel.

How To Extract Cottonseed Oil By Solvent Extraction Method?

The principle of solvent extraction of cottonseed oil is based on the like dissolvent like in chemistry. When the pretreated cottonseed is contacted with hexane extraction solvent (soaking or spraying), the cottonseed oil can be extracted and mixed with solvents. And the solvent is completely evaporated by making use of the different boiling point of oil and solvent, and the cottonseed oil is obtained easily. (Similar project: 10TPD Sunflower Oil Pressing Line Project in Zambia >>)

And the solvent is recycled and it is also suitable for other vegetable oils, like sesame seeds, peanut/groundnut, rapeseed, sunflower seeds, soybeans, etc.

Why Should Buy Small Solvent Extraction Plant For Cottonseed Oil Production?

- High ROI: It requires less investment cost and the ROI is high and quick.

- Easy Operation: The whole tank group for cotton seed oil extraction is easy to operate.

- Energy-saving: The power consumption of this cotton seed oil production line is small. For example, a 10TPD solvent extraction plant only requires 20kw.

- Superior Flexibility: It is suitable for various vegetable oil processing, including rapeseed, peanut/groundnut, sesame seeds, soybeans, etc., which makes it a great investment project for mini, small and medium scale edible oil production factory.

- Easy Maintenances: If there are any production mistakes, it can only shut down the mistaken part for maintenances instead of stopping the whole oil production line. It is very practical in the actual production.

- Low Production Cost: Low solvent consumption, low energy consumption and flexible maintenance help to minimize the oil manufacturing cost.

Start Cottonseed Oil Production Business

Cottonseed oil can effectively help to maintain human health by prevent the rise of cholesterol in blood due to its high linoleic acid content. With the elimination of the public’s negative perception of cottonseed oil and the promotion policies by many countries for cottonseed oil production, there will be a good development in cottonseed oil manufacturing industry. Thus, seizing this opportunity to set up your own cottonseed oil production plant would be a great way to success, especially in countries where cotton is largely planted.

| Cottonseed Oilseed Producer | Production (1000MT) | Cottonseed Oil Producer | Production (1000MT) | Cottonseed Meal Producer | Production (1000MT) |

|---|---|---|---|---|---|

| India | 12,100 | India | 1,390 | India | 4,510 |

| China | 10,400 | China | 1,339 | China | 3,986 |

| United States | 5,665 | Brazil | 618 | Brazil | 1,825 |

| Brazil | 3,927 | Pakistan | 403 | Pakistan | 1,210 |

| Pakistan | 2,729 | United States | 236 | United States | 758 |

| Uzbekistan | 1,273 | Uzbekistan | 197 | Turkey | 586 |

| Turkey | 1,077 | Turkey | 191 | Uzbekistan | 558 |

| EU-27 | 623 | Turkmenistan | 60 | Benin | 174 |

| Australia | 510 | Benin | 58 | Mali | 162 |

| Argentina | 499 | EU-27 | 57 | Turkmenistan | 162 |