Cottonseed Oil Production Line

Introduction to Cottonseed Oil Production Line

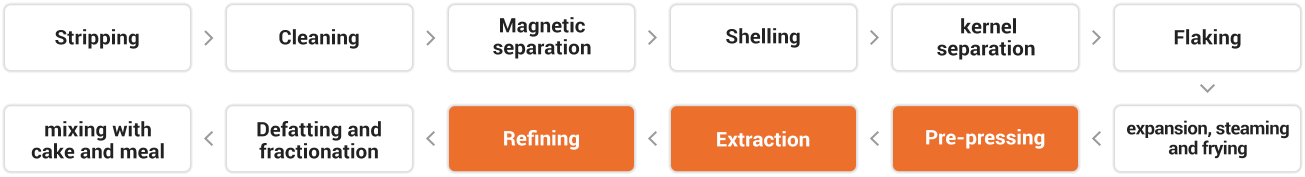

Cottonseed Oil Production Line adopts solvent extraction method to extract cottonseed oil. The cottonseed oil plant includes cottonseeds pretreatment and prepressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery plant. The residual oil rate in the cottonseed meal is lower than 1%. Cottonseeds contain a toxic pigment which called gossypol, of which the content is 0.15%-1.8%. Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock.

Features of Cottonseed Oil Production Line

1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor.

2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration.

3. Cottonseed Oil Production Line has multiple oil extractors for selection and advanced mineral oil system.

4. Adopting negative pressure evaporation system, saving energy and reducing steam consumption.

5. Low residual oil rate in the meal, good oil, and meal quality.

The Process of Cottonseed Oil Production Line

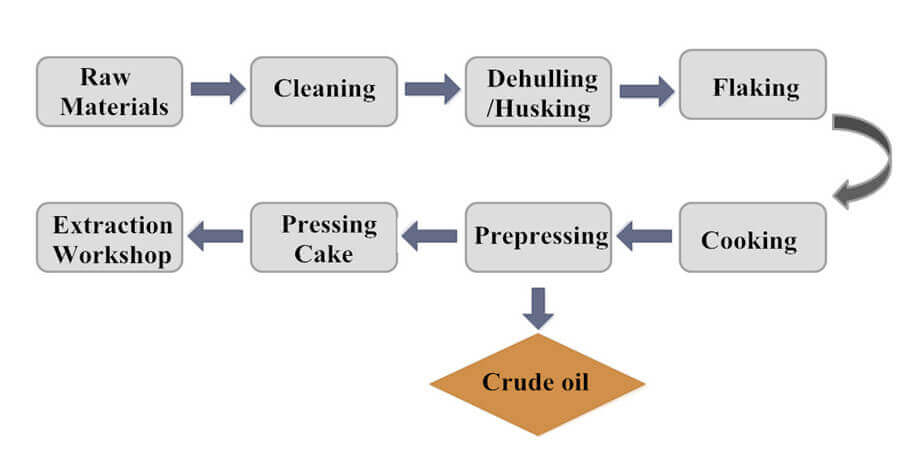

Section I: Cottonseeds Pretreatment and Prepressing Workshop

1. Cottonseed Delinting

If your cottonseeds are with lint, then you need to add cottonseed delinting machine in the cottonseed oil plant.

2. Cottonseed cleaning

Cleaning is to remove the various impurities in the cottonseeds by cottonseed cleaning equipment. Cleaning cottonseeds can reduce oil loss, increase oil yield, and increase the quality of oil, cake, and by-products. reduce the abrasion of equipment, increase the handling capacity, and improve the work environment.

Cottonseed dehulling

Cottonseed contains 40%-55% of hulls and the hull contains only 0.3-1% of the oil. Cottonseed contains 14%-25% of oil and the kernels contain 30-40%. In addition, the hulls also contain brown pigment, pesticide residue, wax, and lint. Hulling cottonseeds can increase the handling capacity of oil press and increase oil yield, improve the quality of crude oil and meal. Cottonseed hulls can be used for cultivating mushroom and used as livestock feed, etc.

The toothed roller crusher in the cottonseed oil mill plant adopts two tooth rollers with different speed to remove the hull. By the extruding and shearing action of the counter-rotating rollers, the hulls are crushed and removed. The toothed roller crusher has the features of large capacity, low power consumption, easy maintenance, high hulling rate, low fines content, high whole kernel rate and the kernels and hulls are easy to be separated.

4. Kernel hull separation

The effect of kernels and hulls separation can affect the oil yield and the quality of oil and meal. Vibrating screen is adopted in the cottonseed oil mill plant to separate kernels and hulls. The hulls are further processed by the hull beater to separate the kernel pieces in hulls. The shaft of the hull beater rotates in different speed and direction with the screen drum. The beating sticks arranged in the spiral on the shaft beat and push the cottonseeds. The hulls and kernels flow out from different outlets of the hull beater.

5. Flaking

The flaking process makes the cottonseeds into flakes and destroys the cell walls, which can largely shorten the oil path to increase the oil-yielding speed and oil yield. Cottonseed oil processing plant adopts hydraulic flaking rollers which can guarantee the uniform thickness of the cottonseed flakes.

6. Cooking

Cottonseed oil processing plant adopts vertical cookers for the cooking process. The flakes from the flaking roller enter the vertical cooker. By high temperature and high moisture cooking, the temperature and moisture of cottonseed flakes are adjusted, the free gossypol content of the crude oil is reduced and the quality of the crude oil is improved.

7. Prepressing

Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant directly. For the capacity of more than 20 tons per day, usually, solvent extraction method is adopted with cottonseed oil pre-press used to extract part of the oil. The machine has a large capacity and the cake has low residual oil rate and is easy for solvent penetration.

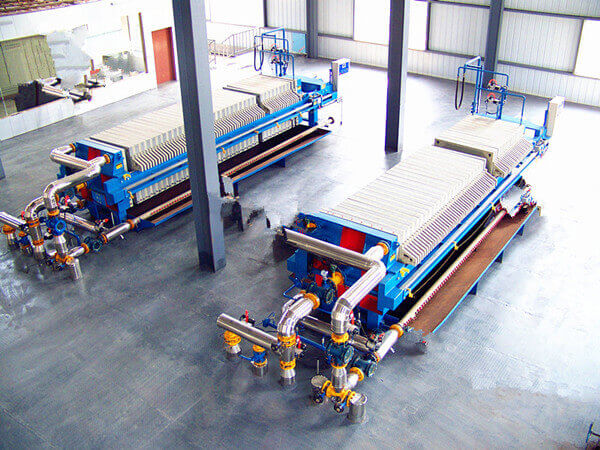

8. Filtration

The oil residue is separated from the oil by the oil residue scraper, and then the oil is filtered by the leaf filter. The filtered oil is pumped into the crude oil tank. The pre-pressed cake is sent to the solvent extraction workshop. The leaf filter used for the cottonseed oil processing plant has the features of high precision, easy to discharge the residue.

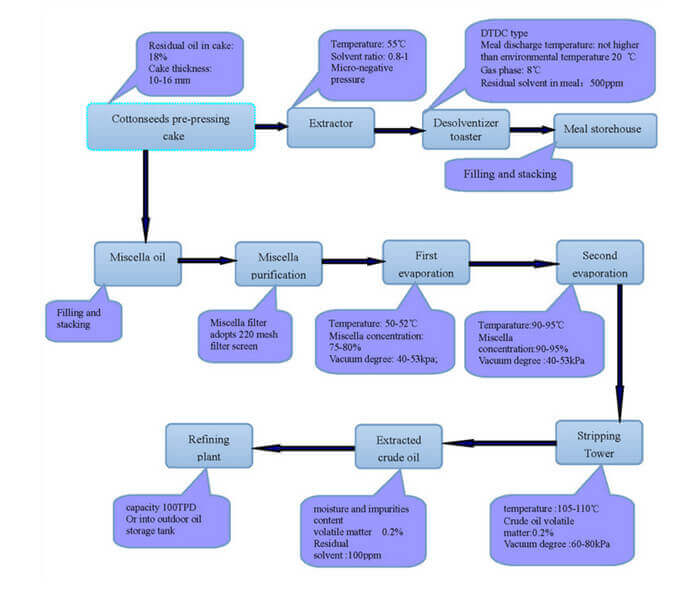

Section II: Cottonseed Cake Solvent Extraction Workshop

Oil Extraction

After pretreatment and cold pressing, the material is transported to the extraction workshop. Oil extraction is using the organic solvent to extract oil from the pre-pressed cake inside the oil extractor. Multiple oil extractors such as loop type, rotocel, and towline extractors can be used for the cottonseed oil extraction plant. After oil extraction, miscella and the solvent containing wet meal are obtained. The miscella is pumped into the hydrocyclone to remove the fines and then the miscella enters the miscella tank in the cottonseed oil extraction plant.

Wet Meal Desolventizing

The wet meal from the oil extractor enters the DTDC desolventizing the Cottonseed Oil Production Line.After pre-desolventizing, desolventizing, drying, and cooling, the solvent is removed and the dry meal is obtained and sent to the meal storehouse for packaging. There is automatic feed valve on the desolventizing layer to keep constant material level.

Evaporating and Stripping

The miscella in the miscella tank enters the first long tube evaporator, the second long tube evaporator and the disk stripping column to remove the solvent. The whole system works under negative pressure. The crude oil obtained goes to the cottonseed oil refinery plant.

d. Solvent recovery: The solvent vapor enters the condensing system. The solvent recycled enters the solvent holding tank for circulation. The wastewater is discharged into the water seal tank. The vent gas in the Cottonseed Oil Production Line enters the mineral oil system for further recovery of solvent. Solvent recovery can reduce solvent consumption and ensure safe production.

Section III: Crude Cottonseed Oil Refinery Plant

Cottonseed oil degumming

The colloidal impurities in crude oil are mainly phosphorus. The presence of colloids such as phospholipids not only reduces the quality of oil but also promotes transitional emulsification between oil and alkali in the alkali refining deacidification process, increasing the difficulty of separation of saponins and aggravating the loss of neutral oil. Therefore it should be removed first.

Cottonseed oil deacidification

Oil deacidification mainly removes free fatty acids in crude oil, as well as a small amount of colloids, pigments, and trace metal substances in the oil.

Cottonseed oil decolorization

The color of the oil and some other impurities must be decolorized to meet product quality standards. At the same time, it provides more favorable conditions for deodorization and refining. Decolorization must meet the final required color index of the product.

Cottonseed oil deodorization

The purpose of oil deodorization is to remove odor-causing substances and other easily volatile substances in the oil, improve the odor and color of the oil, and improve the stability of the oil.

Cottonseed oil refinery machines are divided into three types: batch type, semi-continuous, and full-continuous. They use different capacity oil refining methods, but the final cottonseed oil is all qualified with the standard.

Cottonseed Oil Fractionation

Cottonseed oil fractionation plants can obtain liquid oil and solid fat by cooling crystallization and solid-liquid separation. The plant has the features of advanced technology, fully automatic, high liquid oil yield, and high solid fat purity. Cottonseed oil contains a fair amount of saturated fatty acid and thus has a high melting point. At low temperatures, part of triacylglycerol crystallizes and precipitates, which restricts the application, transportation, and trade of cottonseed oil. By cottonseed oil fractionation, liquid oil and solid fat are obtained. The liquid oil can be used to make mayonnaise and salad dressing. The solid fat can be used to manufacture frying oil, margarine, shortening, cocoa butter substitutes, etc.

Cottonseed Oil Production Video

Cottonseed oil processing plant

The traditional cottonseed oil production process is pre-pressing, extraction, or pressing. Since cottonseed has a high shell content and contains gossypol, it is necessary to peel the shells and use high-moisture steaming and frying during the pre-treatment process to reduce the gossypol content in cottonseed oil.