Ghana Shea Butter Oil Processing Plant Equipment

Ghana is a major global producer of high-quality shea butter oil, with production involving both traditional women's cooperatives and large-scale industrial shea butter oil processing plants. The industry is well-developed, featuring local and international suppliers of processing equipment.

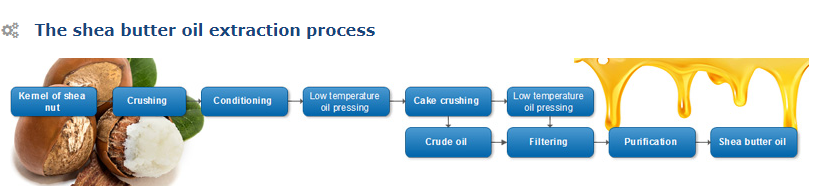

Shea Butter Oil Production Process

Cleaning & Sorting: Raw nuts are screened to remove stones, sand, and debris. Clean nuts ensure your machinery doesn't get damaged.

Crushing & Shelling: The hard outer shells are cracked using a Shea Nut Crusher to release the oil-rich kernels.

Roasting: Kernels are heated to break down oil cells and reduce moisture. Professional Shea Roasting Machines are preferred to prevent burning, which affects the butter's color and scent.

Grinding: The roasted kernels are ground into a thick, chocolate-like paste using a high-speed mill or Colloid Grinder.

Extraction (Pressing): The paste is fed into an Oil Expeller or Hydraulic Press. This applies intense pressure to squeeze out the crude shea oil, leaving "shea cake" as a byproduct.

Refining & Clarification: The crude oil is filtered or centrifuged to remove impurities. For a "refined" grade, it may undergo bleaching and deodorizing to create a white, odorless product.

Cooling & Solidification: The liquid oil is cooled under controlled agitation to ensure a creamy texture without crystallization grains.

Shea Butter Oil Processing Plant Equipment

Core Extraction Equipment (Crude Shea Butter)

- Cleaning Equipment: Vibrating screens (0.37-0.75kW for small scale, air separation combined machines for large scale) to remove dirt and impurities; manual sieves are an alternative for small cooperatives.

- Drying Equipment: Solar dryers (the first choice in Ghana, zero energy consumption) and tray dryers, reducing nut moisture to 8-10% to prevent mildew.

- Cracking & Shelling Machines: Hand-cranked cracker (no power) for small scale, semi-automatic integrated sheller (1.5-3kW) and industrial centrifugal sheller, with a kernel-shell separation efficiency of ≥90%—a key equipment to cut labor costs.

- Roasting Machine: Rotary drum roaster with low-temperature roasting at 60-80℃, prioritizing biomass heating (firewood/palm kernel shell, cheap local fuel in Ghana) to improve oil yield.

- Grinding Machine: Disk mill/colloid mill, grinding roasted kernels into fine paste (≤1mm). Colloid mill (3-7.5kW) is suitable for mid-to-high-end products with an oil yield up to 50%.

- Kneading Tank: 304 stainless steel heated kneading tank, kneading with 80-90℃ hot water for mild saponification (replacing manual kneading); small tanks are equipped with biomass heating.

- Boiling & Separation Tank: 304 stainless steel boiling tank with skimmer, separating crude oil from the top layer after boiling at 95-100℃. The finished crude shea butter has moisture ≤5% and FFA ≤8%.

Refining Equipment (Refined Shea Butter Oil, Export/Cosmetic Grade)

- Melting Tank: Constant temperature melting of solid crude oil at 40-50℃, 304 stainless steel with heating jacket.

- Degumming Reactor: Acid degumming to remove phospholipid impurities, improving oil transparency and shelf life.

- Vacuum Bleaching Kettle + Filter: Decolorization with food-grade activated clay at 80-90℃ under vacuum (-0.08~-0.09MPa), matched with plate/leaf filter for clay separation.

- Vacuum Deodorization Kettle: 316L stainless steel high-temperature deodorization kettle, with steam stripping at 160-180℃ under high vacuum (-0.095~-0.098MPa) to remove natural nutty odor and reduce FFA to below 0.05%.

- Fine Filtration + Cooling Tank: 0.2μm cartridge fine filtration, cooling to 40-50℃ before packaging to prevent crystallization during storage.

Refined Product: Cosmetic/food grade shea butter oil (moisture ≤0.03%, impurities ≤0.01%), odorless white oil for creams, soaps and food additives.(You may also interested in Shea Butter Extraction Plant in Nigeria >>)

Auxiliary Equipment

- Biomass Boiler: Small boiler (50-100kg/h) heated by firewood/palm kernel shell, supplying energy for roasting, boiling and refining (the standard in Ghana, replacing electric boilers).

- Vacuum Pump Set: Water ring vacuum pump (0.5-2kW for small scale) to provide vacuum for bleaching and deodorization.

- Oil Storage Tanks: 304 stainless steel insulated sealed tanks for storing crude/refined oil, preventing moisture and dust contamination.

- Power Supply: 5-20kVA solar/diesel generator for off-grid rural areas; solar generator is the sustainable first choice.

- Packaging Equipment: Semi-automatic filling machine (50g-5kg jars/drums) for small scale, automatic filling line (25kg drums/bulk bags) for industrial scale, with capping/labeling machines.

- Oil-Water Separator: Small 304 stainless steel unit for wastewater treatment, complying with Ghana's environmental regulations.

Types of Ghanaian Shea Butter

| Type | Characteristics | Best For |

|---|---|---|

| Raw/Unrefined | Natural nutty aroma, ivory color, minor impurities (sign of authenticity) | Skincare (dry/sensitive skin, eczema, stretch marks), hair care, massage |

| Refined | Bleached/deodorized, white, neutral scent, smoother | Cosmetic formulations (soaps, lotions, creams), commercial products |

| Organic/Fair Trade | Certified (e.g., Fair Trade, Organic), sustainably wild-harvested, supports women’s cooperatives | Ethical brands, conscious consumers, export markets |

Sourcing & Export (Ghana)

Main regions: Northern Ghana (Tamale, Bolgatanga, Wa) – home to most shea cooperatives.

Certifications: Fair Trade, Organic (EU/USDA), Kosher, Halal (available on request).

Packaging: 50g–25kg (jars, drums, bulk bags); custom packaging for brands.

Export markets: EU, US, Asia, Middle East – used in cosmetics, pharmaceuticals, food (cocoa butter alternative).

QIE Group is specialized in shea butter oil processing plant in africa(ghana, nigeria, togo). We can offer turnkey service for shea butter oil processing plant according to your real conditions. If you want to know more about shea butter oil processing plant equipments, please feel free to contact us.

FAQ

What are the two core processing stages for shea butter oil, and what equipment is the foundation for Ghana’s market?

The two core stages are crude shea butter extraction (from raw shea nuts) and refined shea butter oil refining (for export/cosmetic grade).

Crude extraction equipment is the absolute foundation for Ghana—80% of local shea businesses (especially women’s cooperatives) focus on this stage, with refining as a modular add-on for high-value export.

What grinding equipment ensures a high oil yield (up to 50%) for mid-to-high-end crude shea butter?

A colloid mill (3–7.5kW). It grinds roasted shea kernels into an ultra-fine paste (≤0.5mm particle size), breaking down cell walls more thoroughly than a basic disk mill—this boosts oil yield to 45–50% (vs. 35–40% for disk mills) and produces a smoother crude butter (higher quality for local skincare sales).

What is the final output standard of crude shea butter from Ghana’s semi-mechanical extraction equipment?

Compliant with Ghana’s local market standards: Moisture ≤5%, FFA ≤8%, Impurities ≤1%, ivory/light yellow solid with natural nutty aroma—ready for local skincare/haircare sales or further refining.

Is refining equipment a must for Ghana’s shea processing plants?

No—refining is a modular, optional add-on. It is only required for plants targeting international export (EU/US/Asia) or producing cosmetic-grade shea butter oil (odorless, pale white). Local Ghanaian market sales of crude shea butter do not need refining equipment.

Do equipment suppliers provide on-site training for Ghana’s shea cooperatives/exporters?

Yes—all turnkey equipment packages include free on-site hands-on training (a standard requirement for Ghana’s shea sector). Suppliers send 2–3 professional engineers to train operators on equipment operation, parameter adjustment and daily maintenance. Training materials are provided in English + local Ghanaian languages (for rural cooperatives).

Are wear parts for shea processing equipment locally available in Ghana?

Yes—common wear parts (seals, gaskets, filter cloths, valves, O-rings) are available in Tamale, Accra and Tema (Ghana’s major industrial cities). For special parts (e.g., colloid mill grinding disks, vacuum pump impellers), suppliers provide factory-price fast shipping to Tema Port (3–7 days by air, 20–30 days by sea).