Soybean Sunflower Peanut Edible Oil Processing Line

We been engaged in manufacturing and exporting a huge range of cooking oil processing machines needed in the edible oil processing line, which are used for extracting oil from peanut, soybean, sunflower seed, cottonseed, sesame, palm fruit and so on.

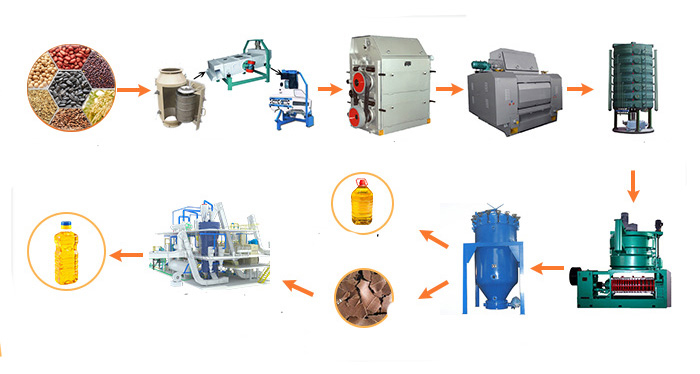

An edible oil processing line for soybeans, sunflowers, and peanuts typically consists of four main sections: pretreatment, oil extraction, refining, and packaging. These lines are customizable for capacities ranging from small-scale (1–10 tons per day) to large industrial operations (30–3,000 tons per day).

Oil seeds pretreatment & pressing:

Oilseed pretreatment & pressing machines are necessary for big capacity cooking oil processing plant oil removing machine, which influences the processing working behind and the quality of crude cooking oil. Oilseed pretreatment & pressing machines oil extractor line include cleaning sieve,stones removal machine, magnetic selection machine, crushing machine, softening machine, flaking machine, drying machine and so on. Because different oilseeds have different pretreatment process, it should be designed by engineers according to customers' needs.

Cleaning: Remove impurities (stones, soil, iron filings, straw, immature seeds) from raw oil seeds to prevent equipment wear, reduce oil loss, and avoid pollution of crude oil.

Shelling: Oil seeds with thick shells (e.g., sunflower seeds have a shell content of 20%–30%) will absorb oil during pressing and reduce oil yield; shelling can also avoid the bitter taste brought by shell components to the oil.

Cracking: Break large oil seeds into small pieces (3–5 mm) to increase the contact area between the seed material and the press screw, and facilitate subsequent flaking.

Flaking: Roll the cracked seeds or shelled kernels into thin flakes (thickness 0.2–0.3 mm) to destroy the tight cell structure of the seeds, making the oil in the cells easier to flow out during pressing.

Conditioning: Adjust the moisture and temperature of the flakes to the optimal state for pressing. Proper heating and moisturizing can denature the protein in the seeds, reduce the viscosity of the oil, and make the oil easier to separate from the solid residue.

Mechanical Pressing: Use a screw oil press to mechanically squeeze the pretreated soybean/sunflower/peanut to extract part of the oil. The pressed cake still contains a certain amount of oil and needs further processing.

Seed-Specific Yield & Cake Residual Oil:

| Oilseed | Pressing Type | Crude Oil Yield | Residual Oil in Cake |

|---|---|---|---|

| Soybean | Hot pressing | 16%–18% | 7%–9% |

| Sunflower Seed | Hot pressing | 35%–40% | 6%–8% |

| Peanut | Cold pressing (high-grade oil) | 40%–45% | 5%–7% |

| Peanut | Hot pressing (mass production) | 45%–50% | 4%–6% |

Oil solvent extraction plant

Solvent extraction plant oil removing machine is a better way to extract oil from oil seeds,and after extracting, the oil residue rate in meal will be less than 1%.Solvent extraction method is very suitable for the oil seeds with low oil content rate.

Solvent Extraction is to use n-hexane to soak the oil cakes, then the oil in cakes will be dissolved in n-hexane, at last, pump the mixed oil,also called miscella. The n-hexane will be evaporated later from the miscella, then by condensing, it can be recycled and used over and over again. (You may also like Soybean Oil Production Line>>)

And for the oil solvent extraction plant oil removing machine, the raw materials have two kinds:

1. The pressed oil cake from the oilseed pretreament &pre-pressing plant, such as the peanut cake, sunflower seed cake.

2. The oil seeds which have been pretreted, can be processing in oil solvent extraction plant directly, such as the soybean, the rice bran.

Oil Refining Plant

Edible oil refining plant is to refine the crude vegetable oil,getting rid of the deleterious impurities, then get the high quality edible oil. According to the different capacities, the vegetable oil refining machine oil removing machine can be devided three types: batch type, semi-continuous type and fully-continuous type vegetable oil refining machine.

Different crude vegetable oil need different vegetable oil refining process oil removing machine. Such as peanut, soybean, sesame,castor, rapeseed etc, the refinery process has four steps: degumming, deacidification,decolorization and deodorization. For corn germ, rice bran,sunflower seed, palm oil, the refinery process has five steps: degumming, deacidification, decolorization,deodorization and dewaxing or fractionation for palm oil. (Read More: 1-1000 TPD Palm Oil Refinery Plant>>)

Degumming: the hydration (degumming) process is water washing oil to achieve the purpose of water precipitation, and water and oil separation automatically. Hydration is the removal of hydrating substances from crude soybean oil. Usually, a certain amount of water is added to crude oil to hydrate the phospholipids, and the hydrate - gelatin is removed by centrifugal separation. Degumming removes not only phospholipids, but also carbohydrates and other sticky substances such as proteins, plant gels and gels. The presence of these impurities in crude soybean oil will increase the loss of oil in the refining process.

Alkali Deacidification: a certain amount of free fatty acids are contained in crude oil. The process of removing these fatty acids is called deacidification. The usual method of deacidification is alkali refining, which refers to adding alkaline water solution to oil (crude oil or hydrated degumming oil) for neutralization and chemical reaction to achieve the purpose of deacidification.

Decolorizing: various oils have different colors because they contain different pigments. Chlorophyll, for example, is grease that turns dark green, and carotene that turns grease yellow. In storage, the sugar machine breaks down the protein and turns the fat brown. The process of decoloring is to repeatedly wash with water, to achieve decoloring purposes. The process is carried out in a vacuum environment.

Deodorizing: different oils have different degrees of odor, some people like, some people do not. Generally, various odors brought by oil are called "stink", and the main substances causing the "stink" in oil are fatty acids, while the content of other stink ingredients is very small. The deodorization process is to remove fatty acids from oil. Oil deodorization makes uses of the differences of fatty acid in oils and fats and other substances in different steam pressure, temperature on the difference of volatility. Under the condition of high temperature and vacuum with the help of the process of water vapor distillation out bad smell. Deodorizing removes unpleasant odors that are volatile in oil.

1. Batch type vegetable oil refining machine:

Core Feature: Processes crude oil in separate batches, with each refining step (degumming, neutralization, bleaching, deodorization) completed sequentially in dedicated tanks or the same multi-functional tank.

Processing Capacity: 0.5–10 tons of crude oil per batch, ideal for small to medium-sized oil mills, rural processing facilities, or startups.

Advantages: Low initial investment, compact footprint, flexible operation (can switch between different oil types easily), simple manual/semi-automatic control, and low maintenance cost.

2. Semi-continuous type vegetable oil refining machine:

Core Feature: Combines batch and continuous processes—pretreatment steps (degumming, neutralization) are often batch-operated, while subsequent steps (bleaching, deodorization) run continuously.

Processing Capacity: 10–50 tons of crude oil per day, suitable for medium-sized oil processing enterprises with stable output demand.

Advantages: Balances investment cost and production efficiency; reduces manual intervention in key refining stages; adaptable to moderate-scale expansion.

3. Fully-continuous type vegetable oil refinery machine:

Core Feature: All refining steps run continuously in a closed, automated production line. Crude oil flows through a series of connected equipment, with parameters (temperature, pressure, reagent dosage) controlled by an intelligent system.

Processing Capacity: 50–5000+ tons of crude oil per day, designed for large-scale industrial edible oil production.

Advantages: High production efficiency, stable product quality, minimal labor cost, low energy consumption per unit of oil, and easy integration with upstream pressing/extraction lines and downstream filling lines.

Key Equipment Configuration of a Refining Plant

| Plant Type | Main Equipment |

|---|---|

| Batch Type | Multi-functional refining tank, heating system, filter, vacuum pump |

| Semi-Continuous Type | Degumming tank, neutralization tank, continuous bleaching unit, deodorization tower, centrifuge |

| Fully Continuous Type | Automated degumming/neutralization unit, continuous bleaching line, high-vacuum deodorization tower, PLC control system, centrifuges, heat recovery system |

Advantages

- Multi-Oilseed Compatibility: Switch between soybean, sunflower, and peanut oil production in 2–4 hours with minimal equipment adjustments.

- Cost-Effective: Shared core equipment reduces investment by 20–30% compared to building three separate single-oilseed lines.

- Flexible Yield Control: Adjust pressing/extraction parameters to meet different oil quality requirements (e.g., cold-pressed peanut oil for high-end markets, hot-pressed soybean oil for mass markets).

- Compliance with International Standards: Final refined oil meets EU Codex Alimentarius, US FDA, and local food safety standards (e.g., Nigeria SONCAP, Ghana FDA).

Soybean Sunflower Peanut Edible Oil Processing Line FAQ

Why is dewaxing needed for sunflower oil but not for soybean or peanut oil?

Sunflower crude oil contains high levels of waxes (0.1%–0.5%), which cause turbidity and precipitation at low temperatures (below 10°C). Dewaxing (cooling crystallization + filtration) ensures the oil remains clear and meets edible quality standards. Soybean and peanut oils have negligible wax content, so dewaxing is unnecessary.

Do I need a solvent extraction unit?

- No need if you choose hot pressing and accept 6%–10% residual oil in press cakes (suitable for small/medium scales).

- Recommended for large-scale lines: solvent extraction recovers residual oil from press cakes, increasing total oil recovery rate to ≥98% and maximizing profitability.

Can the line switch between processing different oilseeds?

Yes. The line is designed for flexible switching with simple adjustments:

For soybean → sunflower/peanut: Activate the shelling unit and adjust flaker thickness/conditioning temperature.

For peanut → soybean: Deactivate the shelling unit and reset process parameters. Switching takes 2–4 hours (no additional equipment required).

What are the key differences in pretreatment for soybean, sunflower, and peanut?

| Oilseed | Key Pretreatment Differences |

|---|---|

| Soybean | No shelling required; focus on cracking into 3–5 mm pieces and conditioning to 80–90°C (10%–12% moisture). |

| Sunflower Seed | Mandatory shelling (kernel purity ≥95%) to avoid bitter taste; flake thickness 0.25–0.35 mm; condition to 90–100°C (8%–10% moisture). |

| Peanut | Shelling + optional red coat removal; crack into 2–3 mm pieces; cold pressing requires tempering at 40–50°C (6%–8% moisture), hot pressing at 100–110°C (8%–10% moisture). |