How to Start a Groundnut Oil Processing Plant

QIE Group is the leading groundnut oil press machine manufacturer and complete groundnut oil production plant supplier. Every year, we will export hundreds of groundnut oil processing machines and setup many groundnut oil processing plant, including oil extraction and oil refining, to many countries, such as Nigeria, Zambia, Ghana, Tanzania, South Africa, India, Philippines, Korea, Australia, Mexico, America, Turnkey and more. Therefore, we are absolutely the professional designer for your groundnut oil production plant. Offer Groundnut Oil Processing Plant with production output 10~5000 ton/day.

Start a peanut oil mill plant is a viable business, especially in regions like Nigeria, Ghana, India, and Senegal where groundnuts are a staple crop and demand for edible oil is high.

Start a Small Scale Groundnut Oil Processing Plant

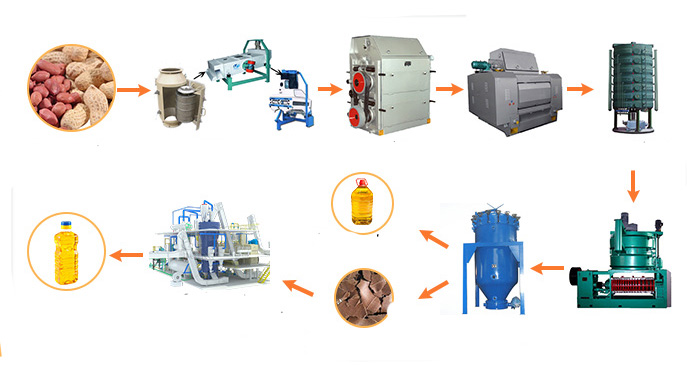

Launching a small-scale groundnut oil processing plant stands as a practical, low-risk entrepreneurial venture ideal for aspiring business owners targeting local and regional markets—especially in peanut-rich regions like Nigeria, Ghana, India, and Senegal, where groundnut oil is a dietary staple and demand for affordable, locally sourced edible oil remains consistently high. With a daily processing capacity of 1 to 20 tons of raw peanuts, this compact setup balances accessibility and profitability, requiring minimal initial investment, simple technical expertise, and flexible operation that adapts to local consumption habits and resource availability.Whether operated as an on-site service for farmers, a neighborhood processing hub, or a small-batch supplier to local markets, a small-scale groundnut oil processing plant combines ease of setup with long-term resilience, making it a compelling choice for entrepreneurs seeking to tap into the steady demand for essential food products. (Read More: A Complete Guide to Peanut Oil Production Line>>)

Cleaning: Raw peanuts are passed through a cleaning sieve and magnetic separator to remove stones, dirt, and metallic impurities that could damage the press.

De-hulling (Shelling): A peanut decorticator removes the outer shells. Efficient shelling is critical, as shells can absorb oil and reduce the overall yield.

Crushing: The peanut kernels are lightly crushed to increase the surface area for oil release.

Roasting/Cooking: For traditional "hot-pressed" oil, a drum roaster adjusts the moisture and temperature (usually 110–120°C). This enhances the nutty aroma and makes the oil easier to extract.

Pressing: The prepared material is fed into a screw oil press. The mechanical pressure of the rotating screw squeezes the oil out of the peanuts.

Filtration: The crude oil contains "foots" (solid particles). It is passed through a plate and frame oil filter to remove these impurities.

Clarification: The oil is often allowed to settle in tanks to ensure a clear, bright appearance before packaging.

Machines of Small Scale Groundnut Oil Processing Plant

Groundnut Shelling Machine

Groundnuts need to be shelled before oil extraction. Shelling can not only increase the production capacity of groundnut oil processing machine and improve the efficiency of oil extraction, but also reduce the wear of groundnut oil processing machine. Groundnut shelling machine is a commonly used machine in the groundnut oil processing process.

Groundnut Cleaning Machine

Groundnut cleaning machine is used to remove impurities such as leaves, sticks, stones, sand, dirt, spoiled seeds and metal contaminants. Examples include magnetic selector, de-stonner and vibrating cleaning sieve. Groundnut cleaning avoids damage to other groundnut oil processing machines.

Groundnut Crushing & Flaking Machine

Groundnuts need to be crushed before oil extraction because of their large size. In addition, since groundnuts have a high oil content, groundnut oil flaking machine may not be required if the yield is small. The function of the groundnut crushing and flaking machine are to increase the contact area between the groundnuts and the groundnut oil pressing machine, which is more conducive to the oil press.

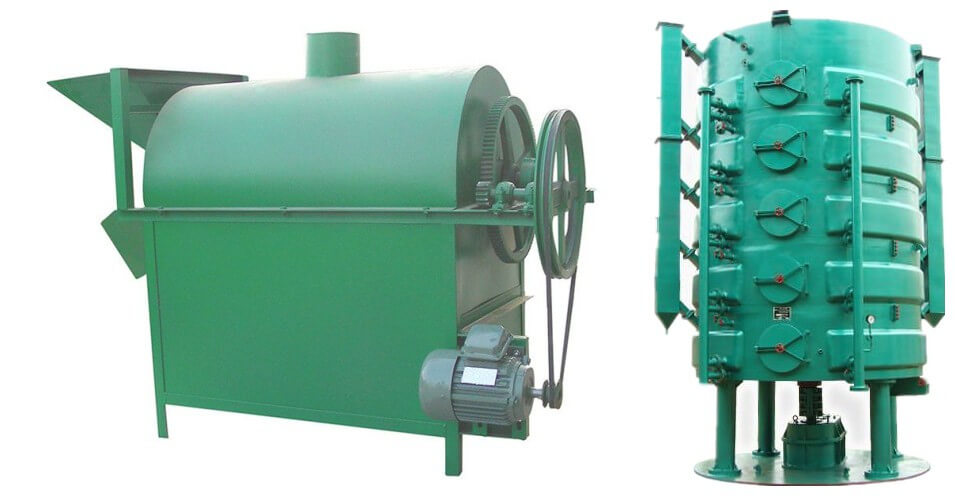

Groundnut Roasting Machine

While not all groundnut oil processing plants roast groundnuts before oil extraction, roasting can enhance the groundnut oil's flavor and quality. Groundnut roasting machine ensures uniform heating and improves the taste of the final oil product.

Groundnut Oil Pressing Machine

The heart of the groundnut oil processing machine is the groundnut oil pressing machine, which presses the oil out of the groundnuts through mechanical force. For a small scale groundnut oil processing plant, a screw groundnut oil pressing machine is typically used due to its efficiency and moderate cost. QIE Group is your best choice for this. In addition to screw groundnut oil pressing machine, we also have integrated groundnut oil pressing machine. Integrated groundnut oil pressing machine has the unique features, such as less dimension, high oil extraction rate, low energy consumption and high automatic degree.

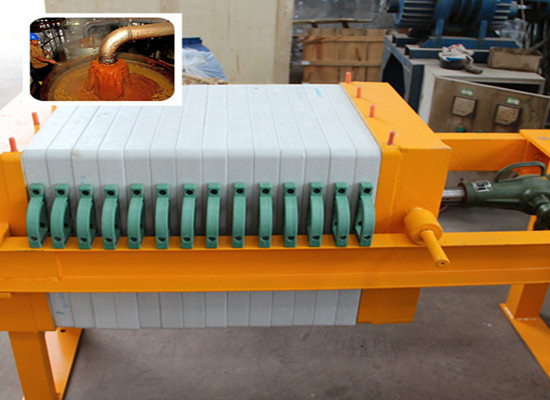

Groundnut Oil Clarification and Filtration Machine

After oil extraction, the crude groundnut oil contains impurities that need to be removed. An groundnut oil clarification machine uses centrifugal force to separate solid particles from the liquid, improving the groundnut oil's clarity. Post-clarification, a fine filtration process is necessary to meet standards for consumer-grade groundnut oil. Plate and frame filtration machine is commonly used for this purpose. Finally, the groundnut oil is bottled and stored and can be sold.

How to Open a Large Scale Groundnut Oil Mill Plant?

Launching a large-scale groundnut oil mill plant represents a strategic and promising venture in the global edible oil industry, leveraging the enduring demand for high-quality, nutrient-rich groundnut oil and the commodity’s widespread cultivation across tropical and subtropical regions. Peanut oil, celebrated for its distinct flavor, high smoke point, and abundant unsaturated fatty acids, remains a staple in households, restaurants, and food processing facilities worldwide—driving consistent market demand that spans emerging economies with growing consumer purchasing power and mature markets seeking premium, natural edible oil options. As the global edible oil market continues to evolve, with increasing emphasis on natural, non-GMO, and sustainably produced products, a well-executed large-scale groundnut oil mill plant stands poised to capitalize on these trends, delivering long-term value to investors, supporting agricultural supply chains, and meeting the evolving needs of consumers worldwide. (Related Post: Start a Peanut Oil Processing Plant>>)

A large-scale groundnut oil mill plant is designed for continuous, high-efficiency production of edible groundnut oil, with a daily processing capacity ranging from 20 tons to 500+ tons of raw groundnuts. The process integrates mechanical pretreatment, oil extraction, refining, and optional fractionation, adhering to food safety standards and maximizing oil yield and quality.

Pretreatment Process

Before oil production, there are certain requirements on the technical properties of oil, so raw materials (peanut) must be pretreated. Pretreatment for peanut oil extracting generally includes: cleaning, crushing, embryo rolling, steaming and stir-frying, etc. The equipment for peanuts pretreatment are cleaning sieve, flaker, cooker and more. All the equipment can be connected by seed conveyor to transfer all the materials automatically, saving labors and eliminating wastes.

Cleaning & Grading: Vibrating sieves, destoners, and magnetic separators remove debris, stones, and metals that could damage industrial equipment.

Shelling (Decortication): Industrial shellers separate kernels from husks with a shell-in-kernel rate of less than 0.5%.

Crushing & Flaking: Rollers crush kernels into 4–6 pieces and then roll them into thin flakes (0.15mm thickness). This breaks down cell tissue to create a massive surface area for oil release.

Conditioning: Flakes are steamed and cooked at 110°C–115°C to adjust moisture to 5%–7%, making the oil easier to squeeze out.

Oil Extraction

Large-scale plants typically use solvent extraction (for maximum yield) or expeller pressing (for cold-pressed oil, with lower yield but premium quality).

Solvent Extraction (Most Widely Used for Large Scale)

This method is suitable for plants with daily capacity >50 tons, achieving an oil yield rate of 95%–98%.

Step 1: Extraction in Extractors

Cooked flakes are fed into a rotary basket extractor or loop-type extractor. Food-grade hexane (solvent) is sprayed countercurrently on the flakes to dissolve the oil.

The resulting mixture is called miscella (oil + hexane), and the residue is meal (hexane-wet groundnut meal).

Step 2: Miscella Distillation & Solvent Recovery

Miscella is heated in a distillation tower (temperature 80–90°C) to vaporize hexane, leaving crude groundnut oil.

Hexane vapor is condensed into liquid in a condenser and recycled back to the extraction unit (solvent recovery rate >99%).

Step 3: Meal Desolventizing & Toasting

Wet meal is sent to a desolventizing-toasting (DTD) machine to remove residual hexane (to <50 ppm) and toasted at 120–130°C to improve protein quality (meal can be sold as animal feed or protein concentrate).

Expeller Pressing (For Premium Cold-Pressed Oil)

Cooked flakes are fed into large-scale screw expellers (with multiple stages of compression).

Oil is squeezed out under high pressure (15–20 MPa) and collected through a filter screen.

Advantages: No chemical solvent, produces high-quality cold-pressed oil (popular in organic markets).

Disadvantages: Lower yield (85%–90%), higher residual oil in meal (5%–7%).

Crude Peanut Oil Refining

Crude peanut oil contains multiple impurities, such as gums, acids, pigments, and off-flavors. Refining is therefore divided into four essential steps: degumming, deacidification, decolorization, and deodorization, some processes also include dewaxing (for wax-containing oils such as sunflower seed oil and rice bran oil).

Degumming: Removing Phospholipids for Stability

In crude peanut oil, phospholipids and proteins may seem minor, but they cause turbidity, sediment, and even emulsification. Worse, phospholipids are highly hygroscopic, which accelerates rancidity during storage.

Two main degumming methods are used:

- Water Degumming – Warm water is added, hydrating phospholipids into colloids that can be removed via centrifugation. It is simple and cost-effective but less effective on non-hydratable phospholipids.

- Acid Degumming – Adding phosphoric or citric acid converts non-hydratable phospholipids into hydratable ones for easier removal. This ensures better stability but requires corrosion-resistant equipment.

Deacidification: Controlling Acid Value to Extend Shelf Life

Free fatty acids (FFA) in peanut oil act like “time bombs.” They cause rancid flavors, shorten shelf life, and prevent oils from meeting retail and export standards. The core target of deacidification is to reduce acid value, ensuring that refined oil maintains stability during storage.

Two mainstream methods include:

- Chemical Refining (Alkali Neutralization) – Sodium hydroxide reacts with FFA to form soapstock, which is then separated. This method is simple but causes some oil loss and requires wastewater treatment.

- Physical Refining (Steam Distillation) – FFAs are removed under vacuum with high-temperature steam. It minimizes oil loss, suits high-acid crude oil, and is more eco-friendly, though it requires higher equipment investment.

Decolorization: Improving Appearance and Market Acceptance

Adsorption by activated bleaching earth. A small amount (0.5–2%) of bleaching earth is added to oil after deacidification. Its porous structure absorbs pigments, oxidation products, and residual impurities. After vacuum filtration, the oil becomes clear and bright. In edible oil trade, color index (measured by Lovibond scale) is a critical inspection standard, especially for international business.

Deodorization: The Final Step for Flavor Purity

Even after degumming, deacidification, and decolorization, peanut oil may still retain volatile compounds like aldehydes or ketones. Principle: Steam deodorization – Under vacuum, oil is heated to 180–240°C and treated with steam, which carries away volatiles.

Key control points:

- Temperature – Too low leaves odors; too high degrades nutrients.

- Vacuum – Higher vacuum helps remove volatiles and reduces oxidation.

- Time – Balanced to avoid excess energy use or oil loss.

Peanut Oil Refinery Plant Type

Peanut oil refinery plants are generally categorized into: batch type, semi-continuous plants, and fully continuous plants.

Batch Type

Batch refining is a discontinuous process where each refining step (degumming, neutralization, bleaching, deodorization) is completed in a single tank before moving to the next stage. It is suitable for small to medium-scale plants (daily capacity: 1–20 tons of crude oil).

Advantages: Low equipment investment, simple operation, flexible to adjust for small batches of crude oil with varying quality; ideal for startup plants in regions like Nigeria and Ghana with fragmented raw material supply.

Semi-Continuous Refining

Semi-continuous refining combines batch and continuous operations: degumming and neutralization are batch processes, while bleaching and deodorization are continuous. It is a cost-effective option for medium-scale plants (daily capacity: 20–50 tons of crude oil).

Advantages: Balances investment cost and production efficiency; suitable for plants that need to process multiple batches of crude oil daily while controlling equipment expenditure.

Full-Continuous Refining

Full-continuous refining is a fully automated, uninterrupted process designed for large-scale plants (daily capacity: 50+ tons of crude oil). All steps (degumming, neutralization, bleaching, deodorization) are connected in a closed pipeline system, controlled by PLC (Programmable Logic Controller).

Advantages: High production efficiency, consistent oil quality, low labor cost, minimal oil loss; meets international standards (e.g., Codex Alimentarius, FSSAI) for large-scale edible oil supply.

Top Groundnut Oil Producers (2024/2025 Marketing Year)

Based on recent data from the U.S. Department of Agriculture (USDA) and market analysis, the leading countries in peanut oil production are:

| Rank | Country | Production (1000 Metric Tons) | Share of Global Production |

|---|---|---|---|

| 1 | China | ~3,104 | ~39% |

| 2 | India | ~1,256 | ~14% |

| 3 | Nigeria | ~265 | ~7.3% |

| 4 | Myanmar | ~267 | - |

| 5 | Sudan | ~159 | - |

| 6 | Brazil | ~144 | - |

| 7 | Tanzania | ~140 | - |

| 8 | United States | ~116 | ~5% (of peanut crop) |

FAQ

What are the key factors to consider before starting a groundnut oil plant?

Raw Material Supply: Ensure stable access to high-quality groundnuts (check local yield, purchase price, and storage conditions—critical for tropical regions to avoid aflatoxin contamination).

Market Demand: Analyze local preferences (e.g., cold-pressed vs. refined oil, bulk vs. packaged sales) and competition (local small mills vs. imported brands).

Regulatory Compliance: Secure permits from food safety authorities (e.g., NAFDAC in Nigeria, FSSAI in India, FDA in Ghana) and environmental clearances for waste disposal.

Scale Selection: Match plant capacity to raw material supply and market size (small: 1–5 tons/day; medium: 5–20 tons/day; large: 20+ tons/day).

How to conduct a feasibility study for the plant?

Market analysis (demand, pricing, distribution channels).

Technical analysis (equipment selection, process design, energy requirements).

Financial analysis (initial investment, operating costs, break-even period, ROI).

Risk assessment (raw material price fluctuations, regulatory changes, climate risks for groundnut crops).

What is the core process flow for a small-to-medium groundnut oil plant?

Raw Groundnut Reception → Pre-cleaning → Shelling & Kernel Separation → Conditioning → Flaking → Cooking → Oil Extraction (Expeller Pressing/Solvent Extraction) → Crude Oil Refining (Batch/Semi-Continuous) → Packaging & Storage

What are the key raw material requirements for groundnut oil processing?

Moisture content: 6%–8% (prevents mold and ensures efficient pressing).

Kernel purity: ≥98% (minimizes oil absorption by shell fragments).

Aflatoxin level: Below local safety limits (e.g., ≤20 ppb in Nigeria and India) to avoid product rejection.