Shea Butter Extraction Plant in Nigeria

Shea butter is used as an edible oil and as an antimicrobial in pharmaceutical applications and as moisturizer in cosmetic industries. Because of its high nutritive value and low cholesterol levels, shea butter is an excellent alternative to table oil. Conventionally, shea butter is widely used in the treatment for ailments such as leprosy. It is also put to use in various industrial applications including soap making, cosmetics, lubricants and paints. Shea butter is ideal for use as a raw material for cooking oil, margarine, cosmetics, soap, detergents and candles due to the presence of solid fat (stearin) and liquid oil (olein) and is used extensively in food industries.

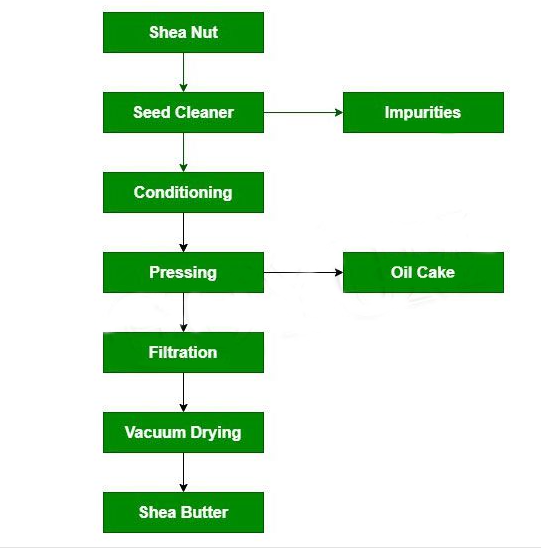

A Shea Butter Extraction Plant in Nigeria is an industrial facility designed to efficiently extract shea butter from shea nuts using mechanical pressing or solvent extraction methods, often in West Africa where shea trees grow. The process involves preparing the shea kernels, such as cracking and crushing them, before extracting the oil using a screw press or a solvent like n-hexane. The resulting crude shea butter can then be filtered, evaporated, and optionally refined for various uses in cosmetics, food, and pharmaceuticals.

Shea Butter Extraction plant Process

Shea butter oil extraction technology , shea butter oil extraction machine for high quality shea butter oil making: buy shea butter oil extraction machine from oil mill machinery manufacturer

Mechanical processing technology

Mechanical processing technology referred to as the Cold Press Extraction method, does not involve the various different heating stages involved in traditional processing.

The mechanical press method of shea butter extraction has been reported by FAO and CFC (2002) but one of the earliest research on the use of the mechanical press was by Marchand (1988). His research revealed that equipped with a jack that exerts 30 tonnes of force, a shea butter press could crush more than 3 kg of shea kernels within 20 minutes. The press could extract up to 85% of the fat contained in the kernel in a simplified process (Marchand, 1988) through a reduction in the various heating stages of the kernel.

The processing of shea butter by this technique is carried out in a plant comprising of a boiler, mechanical press system and a filter press system. The mechanical press applies a great deal of pressure to the pulverized seed to turn out more shea butter from the process. Other inventions targeted single unit operations among which were a kneading machine, grinders, a hydraulic hand press, solar dryers, a heater and mixer. About 30–33% of shea butter is extracted from the shea nuts with the mechanical expeller although combination of the mechanical with chemical methods has achieved 98% extraction efficiencies.

The chemical extraction processes

The principle with solvent/hexane extraction is that, the pulverized kernel is mixed with hexane which then unlocks the polymeric mass allowing all the oily and fatty constituents of the kernel to dissolve in it.

The types of the solvents used in the extraction have some influence on the quality characteristics of shea butter especially the peroxide value of the butter. In a study conducted by Kar et al. (1981), on the best solvent for shea butter extraction, petroleum ether, n–hexane, chloroform, benzene, and water were employed. Hexane extraction gave the highest amount of fat from the kernel. The principle with hexane extraction is that, the pulverized kernel is mixed with hexane which then unlocks the polymeric mass allowing all the oily and fatty constituents of the kernel to dissolve in it. The resulting oil–hexane mixture is later separated from the seed residue by filtration. The oil–hexane mixture is then heated to 68ºC to vaporise and recover the hexane to obtain the crude Shea Butter. The use of chemicals in the extraction process takes shea butter away from being a natural oil. However, the improved quality of the residual meal, reduced fibre content, preserved protein properties of defatted meal, low–peroxide and reduced free fatty acid values are some of the reasons which make enzyme processes more economical for oil extraction processes.

A Shea Butter Solvent Extraction Plant is an industrial facility that uses chemical solvents to extract oil from the kernels of the shea tree, producing shea butter. This method is particularly effective for maximizing oil yield and is often used in larger-scale shea butter production.

Here's a more detailed breakdown:

1. Purpose:

· To extract shea butter (the oil) from shea nuts (the kernels of the shea tree) in a more efficient and industrial manner than traditional methods.

· To achieve higher oil yields compared to mechanical pressing methods.

2. Process:

· Crushing/Grinding: The shea nuts are crushed or ground into a smaller size to facilitate oil extraction.

· Solvent Extraction: A solvent, such as n-hexane or petroleum ether, is used to dissolve the oil from the crushed nuts.

· Filtration: The solvent-oil mixture is filtered to remove any remaining solid debris.

· Solvent Evaporation: The solvent is evaporated, leaving behind the pure shea butter.

· Refining (Optional): The shea butter may be further refined through processes like neutralization, bleaching, and deodorization to improve its quality and purity.

3. Key Equipment:

· Seed Cleaner: To remove impurities from the nuts.

· Crusher/Grinder: To reduce the size of the nuts.

· Soxhlet Extractor: A device that uses a solvent to extract the oil.

· Evaporator: To remove the solvent after extraction.

Refining Equipment: (Optional) For further purification and process

Top Exporting & Importing Countries of Shea Butter

- Nigeria is the leading exporter of Shea butter in the world and the Shea tree is grown in about 21 States of the 36 available in Nigeria.

- China is the leading importer of Shea butter in the world.

Data shows that Nigeria ranks as the highest producer of shea butter globally, despite challenges with production, storage, electricity and others.

- Nigeria with 39.87% (302.96k metric ton)

- Mali – 29.76% (226.09k metric ton)

- Burkina Faso – 18.43% (140.04k metric ton)

- Ghana – 4.18% (31.59k metric ton)

- Ivory Coast – 4.16% (31.59k metric ton)

- Benin – 1.83% (13.91k metric ton)

- Togo – 1.76% (13.39k metric ton)

Shea butter produced in Nigeria has a very good quality and is abundant in quantity, especially during the peak period (June – November). This availability of the raw produce helps international buyers get it at a competitive price.

There is a very large demand for agricultural produce in Nigeria, with many international buyers always looking for products that are cheap and are of the best quality.