Small Scale Sunflower Oil Extraction Machine

All kinds of sunflower oil extraction machine with lowest possible price and premium quality, supplied by QIE - one of the best oil machine manufacturers. With great reputaions in seed oil making field, we can offer the most suitable solution for both small and full scale vegetable oil producing business. You can trust both the machinery quality and after-services we offered.

Sunflower oil is extracted from sunflower seeds. It's a highly nutritious edible oil, rich in nutrients such as linoleic acid and vitamin E. It benefits the immune system, can prevent cancer, and due to its antioxidant and anti-inflammatory properties, it can also help prevent asthma. As a result, sunflower seed oil finds extensive commercial and household applications, especially in the food industry.

Why Choose Small Scale Sunflower Oil Extraction Machine?

In rural areas or households, people are increasingly focusing on how to make use of their harvests to produce sunflower oil. One solution is to utilize small-scale sunflower oil extraction machine. Let's explore the advantages of using small sunflower oil machines:

- Portability: Small sunflower oil extraction machines are more light and easier to move and carry.

- Low Cost: Small oil making machine price are lower, so users can start sunflower oil business within their economic means, reducing investment risks.

- Ease of Operation: These machines are usually designed to be user-friendly, equipped with simple control panels and operation buttons.

- Energy Efficiency: Small scale sunflower oil expeller have lower power requirements, which can save energy and reduce costs.

- Fresh Sunflower Oil: Because it's extracted directly when needed, the time between sunflower and oil is short, which ensures freshness and quality of sunflower oil.

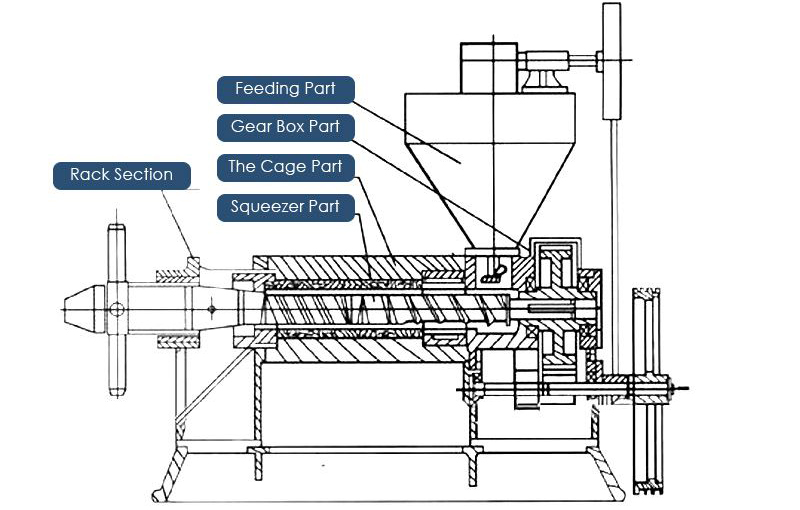

Screw Type Sunflower Oil Extraction Machine: Construction Principle

Next, we will delve into the core structure of small sunflower oil extraction machine, uncovering the functions and roles of its various parts. With this in-depth understanding, you will be able to grasp the essence of the small oil making machine more comprehensively, aiding the success of your business. Structural design of a small screw press typically includes several components:

- Feeding System: It is responsible for supplying the raw materials for processing in the oil press. It comprises a feeding hopper, feeding screw, and other components. The feeding hopper holds the raw materials, while the feeding screw pushes the raw materials from the hopper into the oil pressing chamber.

- Pressing System: It is the core part of the oil pressing machine and consists of the pressing screw and pressing chamber. The pressing screw is a screw-shaped metal rod with a design that gradually increases the pitch. The pressing chamber serves as the casing for the screw, where the screw rotates.

- Heating System: It is used to heat the oil pressing chamber as needed to improve the fluidity of the oil and enhance the extrusion process. This is typically achieved using electric heaters or steam heaters, allowing the temperature during the oil pressing process to reach an appropriate range.

- Control System: It monitors and controls the operational parameters of oil making machine, such as temperature, pressure, and speed. It ensures the stability and safety of the oil extraction process and optimizes the oil extraction efficiency by adjusting parameters.

QIE has emerged as a renowned manufacturer and supplier of edible oil processing machinery. Our expertise and experience in this field have earned us a global reputation. We offer a wide range of products, including oil machines for home and commercial and refining equipment, capable of processing various oil-bearing seeds and nuts. For more information, please feel free to contact us at any time!

Using Small Sunflower Oil Extraction Machines

Sunflower oil making machine price can be influenced by various factors, including machine size, quality, brand, and manufacturer. Here are some common price ranges for your reference:

- Low Range: These cheaper machines might be smaller in scale and lower in performance, but they can still be used for small-scale oil pressing operations.

- Mid-range: Price ranges usually fall between a few thousand dollars to around ten thousand dollars. These machinery generally offer good performance and durability, suitable for small and medium-scale oil making plant.

- High Range: Higher price range, usually exceeding ten thousand dollars. These machinery often come from well-known brands or professional manufacturers, featuring advanced technology and larger capacity, suitable for commercial oil pressing production.

In addition to the equipment purchase cost, you should also consider the following related costs(Related Post:100tpd Sunflower Oil Production Line>> ):

- Transportation Costs: Shipping the equipment from the manufacturer to your location might entail additional transportation costs.

- Installation Costs: Depending on the type and scale of the equipment, you might need to pay for installation to ensure proper setup and operation.

- After-sales Service and Maintenance Costs: Some manufacturers might offer after-sales service and equipment maintenance support, and you should assess the relevant costs based on the actual situation.

Complete Oil Pressing Process

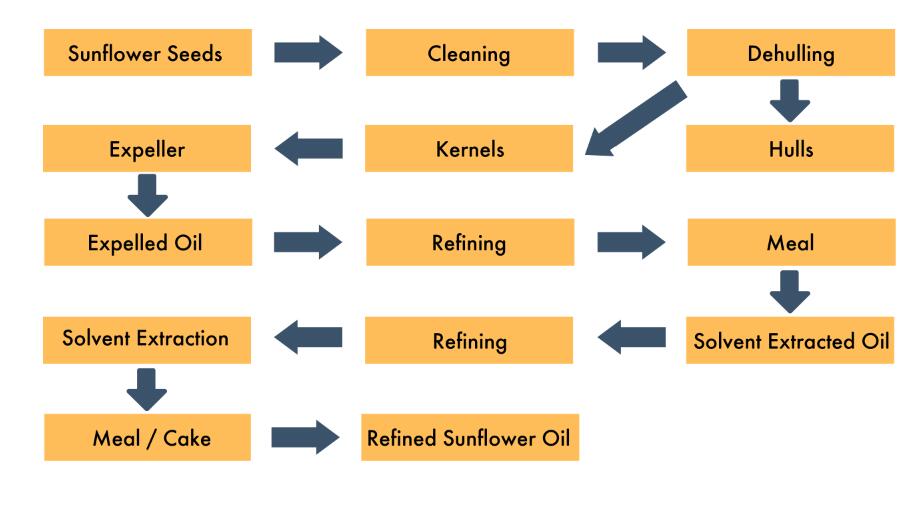

Sunflower seeds are of two types. One the non-oil seed which is usually eaten as confectionery just after being roasted with or without the shell. The other one is oil type seeds which is used for extracting oil. Below is a basic process of sunflower oil pressing. If you are looking for customized business plan for both small scale and large scale sunflower seed oil processing, don't hesitate to contact us and inquire for the most suitable equipment list and cost! (Related Post: Sunflower Oil Production Business Plan >> )

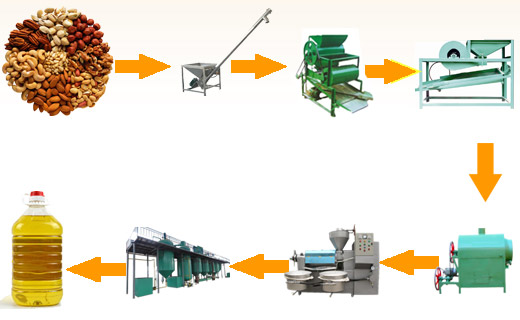

Mini Sunflower Oil Pressing Unit / Line

Seeds Cleanning: The processing starts with cleaning which is done by passing the oil seed over magnets to remove metal traces. Then those seeds are passed through a special machine to remove others matters (dirt).

Seeds De-hulling: The other step is de-hulling though it optional. Here, seeds contain a given percentage of hulls which are sometimes removed right before oil pressing. This is done by cracking the seeds then the resulting content winnowed to separate the hulls.

Grinding: The other step is grinding. The de-hulled seed is then grounded to a meal by mechanized grooved rollers.

Cooking: The resulting meal is then heated (steam cooker) to enhance extraction of oil.

Oil Pressing: Then the meal is processed by sunflower seed oil mill. The meal heated previously is the then fed to sunflower oil press that increase the pressure as the meal moved through the slotted barrel.

Solvent Extracting: Then extraction of additional oil with solvent is done in solvent extraction plant. The initial oil is usually recovered from the screw press, but the oil remaining is extracted here with a solvent, to maximize the yield. Here, the traces of solvent are removed by the use of stripping column. Oil is boiled, solvent floats as it condenses thus removed.

Crude Sunflower Oil Refining: The oil is the refined by heating and mixing it with an alkaline. Though soap forms, the oil is further cleaned to remove traces of soap and then dried. (Read more: Oil Refinery Plant >>)

Oil Packing: Here is where packing is done. lt’s done after completing all the other processing. Now that the oil is pure it's the measured and packed in clean containers of different sizes.

Sunflower Oil Manufacturing Process

Sunflower Oil: Properties and Manufacture

Sunflower plant having the botanical name Helianthus annuus, is the source of one of the most popular vegetable oils, i.e., sunflower oil. Sunflower crop is cultivated in many countries around the world including India. Different types of sunflower seeds are available which contain oils having different unsaturation. Some varieties of sunflower seeds are eaten as a delicious and nutritious snack directly and are known as confectionary (or non-oil) sunflower seeds. Some sunflower seeds have either high oleic acid or high linoleic acid content. Other varieties are used to extract sunflower oil and their crops are called oilseed sunflower crops. Each sunflower seed variety has unique contents of saturated, monounsaturated and polyunsaturated fatty acids. Sunflower oil is used as cooking oil, while the protein-rich deoiled cake or meal is used as a component of animal feed formulations. Several perennial species of sunflower are also grown in gardens.

Sunflower plants, even while growing, tilt to face the sun during the day and gain more sunlight for photosynthesis. This tracking of the sun by the plant is known as ‘heliotropism’. This continues for a short time when the sunflower plant blooms. The young sunflower heads track the sun during the day. Hence their name ‘sunflower’!

The present series of articles discuss the crop cultivation, properties of sunflower oil, their manufacturing and refining methods, applications and commercial aspects.

PROPERTIES

Sunflower seeds contain up to 50% of triglyceride oil and up to 20% protein. Small quantities of waxes are also present in the oil. Considerable amounts of vitamins, minerals and tocopherols (vitamin E) are also present. Magnesium, copper, iron, calcium, zinc, sodium, potassium, phosphorus, selenium, and manganese are found in sunflower seeds. Sunflower oil is also rich in omega-6 fatty acids. Sunflower oil does not contain dietary cholesterol.

Regular sunflower oil typically contains about 69% linoleic (C18:2) acid, about 20% oleic (C18:1) acid, and about 11% saturated fatty acids – stearic (C18:0) acid 6% and palmitic (C16:0) acid 5%. However, a number of strategies have been adopted to present advance range of sunflower oils with elevated levels of oleic acid, stearic (C18:0) acid, linoleic acid and palmitic (C16:0) acid and low saturated fatty acids. Research on new varieties of sunflower seeds is ongoing to try to develop seeds and modify their fatty acid profile to improve functionalities of the oil.

There are four main varieties of sunflower oil which are produced commercially from the respective sunflower seed varieties. These types are – high-linoleic acid, high-oleic acid, mid-oleic acid and high-stearic combined with high-oleic acid. The major fatty acids contents of these varieties are listed in the following table.