100tpd Sunflower Oil Production Line

Raw Material: sunflower seed

Produciton line: Complete oil production line include 100TPD press and pretreatment, 70TPD solvent extraction equipment, 40TPD crude oil refining.

The oil extracted from sunflower seeds is called sunflower seed oil, which is a kind of common oil and plays an important role in people’s daily life. It is golden, clear and bright, and has a pleasant flavor, which is the main cooking oil for many people.

Because sunflower seed oil is rich in nutrition and has a variety of health functions for human body, it is honored as “health care product”, “advanced nutrition oil” or “health oil” in foreign countries. In recent years, it has been sold well in the international market and greatly favored.

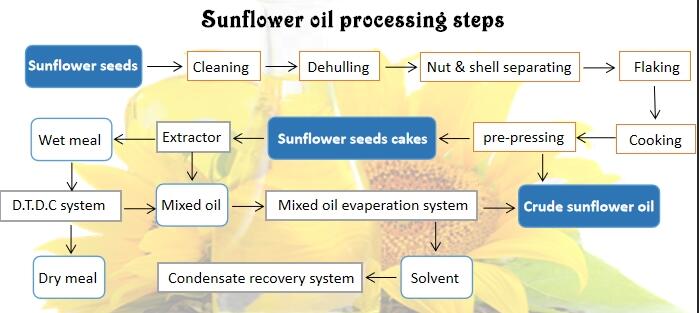

Sunflower oilseed pretreatment

The purpose of preparation is to extract a portion of oil by mechanical pressing while providing pressing cakes for extraction plant. Main processes include: Seed Cleaning & Weighing, Cracking & Dehulling, Flaking, Cooking, Pressing, Oil Residue Separation.

Sunflower oil solvent extraction plant

There are four big parts in solvent extraction workshop.They are solvent system, desolventizing system, condensing system and recycling system. We can get rapeseed wet meal and crude rapeseed oil.Rapeseed wet meal can be as animal feed, crude rapeseed oil contains solid impurity, chemical impurity and smelly odour etc. So crude rapeseed oil can go to next refinery workshop.

Sunflower oil refining plant

There are four big parts in solvent extraction workshop.They are solvent system, desolventizing system, condensing system and recycling system. We can get rapeseed wet meal and crude rapeseed oil.Rapeseed wet meal can be as animal feed, crude rapeseed oil contains solid impurity, chemical impurity and smelly odour etc. So crude rapeseed oil can go to next refinery workshop.(Read More: Sunflower Oil Processing Plant Oil Making Machine Kenya>>)

Technology Feature

Benefits of our professional solutions for sunflower oil processing equipment

1. The complete set of sunflower seeds pretreatment equipment is full continuously and mechanized operation, ensure advanced process indicators, while reduces equipment investment, such as land cost, operating and maintenance costs.

2. The leaching workshop adopts the international level leaching system and low temperature desolventizing machine, achieve higher mixed oil concentration and lower residual oil. Reduce the amount of solvent circulation, energy and dissolution consumption, thus ensuring the lowest level of residual oil and dissolution consumption.

3. The fully closed operation system of the leaching workshop, the full negative pressure evaporation avoids oil oxidation; the separation of crude oil and solvent can be realized at a lower temperature condition, which ensures the quality of leaching crude oil, improves the refining rate and significantly reduces energy consumption.

4. The advanced physical refining process reduces the loss of refining oil and improves the oil quality. The by-products - fatty acids can be directly obtained, helping factories realize the economic benefits of sustainable development. There is no waste water pollution during the process, while meeting the environmental and health requirements.(You may also like: Setup a Complete Cooking Oil Production Plant >>)

What's the Cost of Setting Up the Sunflower Oil Factory?

The setup cost of this sunflower oil mill plant includes the equipment of 100ton/h oil production line, 4 ton/h steam boiler system, and installation and commissioning fee. Actually, each project is customized depends on the clients' specific situation and needs, which meas the cost depends on many differen factors.

- Capacity

- Process Design

- Processing Technology

- Machine Quality

- Other Factors

This 100 TPD sunflower seed oil production is also suitable for, soybean oil, cottonseed oil, rapeseed oil, tea seed oil, peanut oil, corn germ oil, rice bran oil and other oil seeds. And the main equipment includes degumming tank, heat exchanger, centrifuge, decolorizer, deodorization tower, etc.