Sunflower Oil Production Business Plan

Each of the appealing yellow flower head is composed of about 1000s of seeds surrounded by the big petals and it is the presence of these seeds in the sunflower that accounts for sunflower oil industry. Sunflower oil is golden in color, clear and transparent, and has a fragrant smell. It is an important edible oil. It contains a large amount of essential fatty acids such as linoleic acid, which can promote the regeneration and growth of human cells, protect skin health, and reduce the accumulation of cholesterol in the blood. It is a high-grade nutrient oil.

Set Up Small Sunflower Oil Production Line

Main Equipment: Cleaning/screening machine, seeds cooker, oil expeller, oil filter press and conveyors.

This sunflower oil manufacturing unit is effective, automated and affordable which makes it ideal choice for small scale sunflower oil factory. It is capable of continuous cooking oil processing plant.

Sunflower Seed Oil Press Machine

Sunflower oil press is the key equipment of this sunflower oil production line. It is screw type oil expeller that involves a mechanical process of crushing the seeds against a metal head using a giant screw that is the key to continuous squeezing of the oil out of the sunflower seed.

Should Sunflower Seeds be Shelled before Oil Pressing?

In recent years, the most popular processing method of edible sunflower oil is mechanical oil pressing and cold pressing. Many customers are always wondering should the sunflower seed be shelled before oil extraction process. Actually, this is decided by the request of customers.

Make Oil without Shelling

For small scale sunflower oil production line with capacity less than 20T/D, the seeds can be expelled in oil press with shell. This process is very common in small scale oil extraction workshop or family oil milling business. Surely, the shelling process can be included for small scale production line if the customer request.

Make Oil after Shelling

For industrial scale edible oil mill plant with daily capacity more than 20 tons, sunflower seed dehulling machine is necessary. The main process of fully scale sunflower oil processing plant is shelling, pre-pressing, solvent extraction, oil refining and oil filling. (Extract oil after dehulling can reduce the wax content of final oil.)

How To Start Sunflower Oil Manufacturing Business

Sunflower oil is an important edible cooking oil worldwide. Find here a detailed sunflower oil manufacturing business plan checklist for your ready reference.

Basically, sunflower seeds contain 32 to 40% oil. Therefore, it is one of the best oilseeds for edible oil processing globally.

Sunflower oil is light in taste and appearance and supplies more Vitamin E than any other vegetable oil. Basically, it is a combination of monounsaturated and polyunsaturated fats with low saturated fat levels. The versatility of this healthy oil is recognized by cooks internationally.

Currently, Ukraine, Russia, Argentina, and China are the major sunflower-producing countries globally. If you live in a sunflower growing area, then you can consider starting this business.

Sunflower oil manufacturing is a medium to large-scale industry. And definitely, it demands substantial capital investment. Initiating a manufacturing unit is a lucrative opportunity for the entrepreneurs.

Sunflower Oil Market Potential

Domestic demand for sunflower oil has increased in recent years as processors have built refineries and large buyers have committed to future purchases. Food processors use the oil for frying foods (including potato chips) and in salad and cooking oil, margarine, and dairy substitutes.

Sunflower oil is preferred in many high-quality dining establishments for its neutral taste. A small supply of oil is used in industrial frying applications where high temperatures require good oxidation stability. A small amount of oil is also used in cosmetics, resins, and lubricants.

Sunflower oil is valued for its light taste, frying performance and health benefits. Additionally, it meets the needs of consumer and food manufacturers alike for a healthy and high-performance non-transgenic vegetable oil. Apart from cooking oil, it has adequate demand in the cosmetics industry as well.

Sunflower Oil Manufacturing Plant Cost

Broadly, this type of business demands two basic type of investment. One is the fixed capital investment. It includes plant, machinery and other initial costs related to the business. The another is working capital etc. Basically, it includes raw material cost, utility bills, staffing, marketing expenses etc.

If you are looking for the funding only for machinery purchase, then you can go for hire purchase leasing. And for a working capital loan, you can avail cash credit facility from banks.

Machinery

Actually, sunflower oil manufacturing plant is an integrated oil processing, refining, and packaging solution. Basically, the cost of the machinery depends on the desired production output.

Raw Material

The major raw material is sunflower seeds. Apart from this, you have to arrange the packaging consumables for your unit.

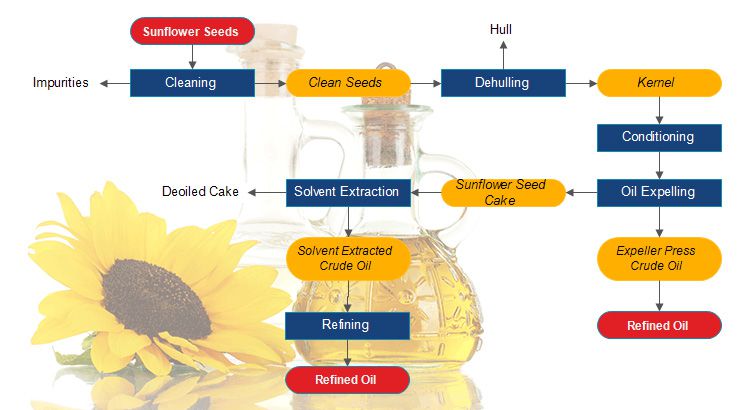

Sunflower Oil Manufacturing Process

The sunflower oil manufacturing process is a complicated oil making process. The detailed manufacturing process includes several steps. The sunflower seed is the fruit of the sunflower which usually contains approximately 40 – 50% oil by weight. Producers should press oil not only from the seeds but the entire head of the sunflower in order to extract the highest oil yield. After the extraction section of

First of all, you have to press oil not only from the seeds but the entire head of the sunflower in order to extract the highest oil yield. After the extraction section of the sunflower oil manufacturing process, you have to send the extracted oil for further refining and filtering. Modern oil extraction techniques create a byproduct called pressed sunflower seed cake or meal. Basically, it is high in protein and you can utilize it for livestock feed.