10-100TPD Palm Oil Refining and Fractionation Line

Palm Oil Refinery is an important process in the palm oil mill plant to ensure the quality and safety of palm oil. It’s recommended to refine crude palm oil through our palm oil refining machines to get high-quality palm oil that is easy to store and can priced high. Refined palm oil can be packed and labeled for the local or global market. We offer you complete palm oil pressing refining plant solutions, from plant layout design to palm oil equipment manufacturing, debugging, and installation.

The 10–100 TPD Palm Oil Refining and Fractionation Line is a compact, cost-effective, and highly adaptable processing solution tailored for small to medium-scale palm oil enterprises, rural processing hubs, and satellite facilities attached to palm plantations. Designed to handle 10 to 100 tonnes of crude palm oil (CPO) per 24-hour operating cycle, this line integrates two core processes—refining (to produce high-quality edible oil) and fractionation (to split oil into value-added liquid and solid fractions)—with a focus on flexibility, low energy consumption, and compliance with international edible oil standards.

Crude Palm Oil Refining Plant Process

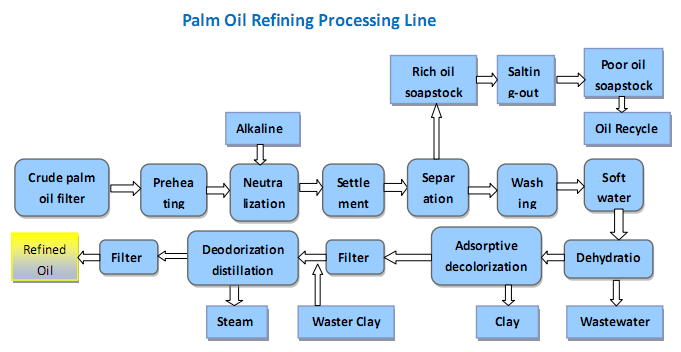

The main steps of crude palm oil refining are degumming, deacidification, bleaching, and deodorization.

CPO(crude palm oil)→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

Degumming

The degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Neutralizationg

Alkali solution (typically sodium hydroxide) is added to neutralize free fatty acids. Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil. We can add some lye to neutralize the free fatty acid, this process is also called alkali refining.

Bleaching

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. All the pigments can be removed by the adsorbents method. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Deodorization

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Palm Oil Refinery Plant Type

| Batch type palm oil refining plant | ||

| Capacity (Ton/Day) | 1-20tpd | |

| Application: |

|

|

| Main equipment: | Refining pot, Decoloring pot, Deodorization tank, Steam generator, Vibrate filter, Electricity distribution control, Air compressor | |

| Semi-continuous palm oil refining plant | ||

| Capacity (Ton/Day) | 20-50tpd | |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. | |

| Main equipment: | Refining reactor, Decolorization reactor, Vibrating filter, Deodorizing tower, Deodorized oil pump, Centrifugal water pump, Heat conductive oil furnace | |

| Fully continuous palm oil refining plant | ||

| Capacity (Ton/Day) | 50-1000tpd | |

| Application: | Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil, groundnut oil, etc. | |

| Main equipment: | Washing centrifuge, Vacuum dryer, Decolorization tower, Decolorization oil pump, Plate filter, Deodorization tower, Cooling tower, Thermal oil furnace | |

Palm Oil Fractionation Plant

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) andmiddle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in0’C to ensure it can keep flow ability and transparency in the refrigerator and improve the quality andappearance of palm oil.

The process of palm oil fractionation includes :

• Preheating the feed stock to give a homogenous mass with nil solids.

• Crystallisation under preset controlled conditions of temperature & agitation to form stable, uniform sized filterable crystals.

• Filtering on membrane press filter (or Rotary Drum Vacuum filter) to separate the solid/liquid fractions.

Main Features & Advantages of palm oil Dry Fractionation

• Combines all operations, and monitors from a fully automated centralized control station.

• Easy to operate, requires minimum supervision.

• Good flexibility. Wide range of process applications possible.

• Feedstock can be crude, semi refined or fully refined palm oil.

• Suitable for both single or double fractionation.

• Minimum operating costs.

- Low utility consumption

- Low maintenance costs

- No oil losses

- No pollution problem

• Product quality.

- Good crystallization repeatability, yielding consistent product quality

- High olein yields

- Low olein cloud point, with improved cold stability, Cloud point as low as 2 °C with iodine value of

65.0 can be obtained

Palm oil in the world, is widely used in cooking and food manufacturing. It is used as cooking oil, crispy fat and margarine to use. The same as other edible oil, palm oil can be easily digested, absorbed, and promote human body health.

FAQ

Q: What products are produced during fractionation?

A: Fractionation is a physical process that separates refined palm oil into components without chemicals:

Palm Olein: A liquid fraction used as high-quality frying oil.

Palm Stearin: A solid fraction used for margarine, shortening, and industrial fats.

Palm Mid-Fraction (PMF): A specialized component used in chocolate and confectionery.

Q: What core processes are included in the line?

A: The line combines two integrated systems with optimized workflows for small-to-medium throughput:

Palm Oil Refining System (2 configuration options)

Chemical Refining (standard): Degumming → Neutralization (alkali treatment for free fatty acids/FFA) → Bleaching (activated clay for pigments) → Deodorization (high-temperature vacuum steam stripping).

Physical Refining (optional): Degumming → Bleaching → Deodorization (steam stripping removes FFA directly, no neutralization step).

B. Palm Oil Fractionation System

Crystallization: Controlled cooling of refined oil (20–30°C) and holding period to form palm stearin crystals.

Separation: Solid-liquid separation via filter press (10–30 TPD) or decanter centrifuge (30–100 TPD).

Optional Hardening: Hydrogenation module to adjust the melting point of stearin for specialized applications.

Q: What are the space and utility requirements for the line?

A:

| Capacity Range | Total Space Requirement (Indoor + Outdoor Storage) | Key Utility Requirements |

|---|---|---|

| 10–30 TPD | 200–400 m² | 380V/415V electricity; 0.8–1.2 MPa steam; cooling water (≤25°C); compressed air (0.6–0.8 MPa) |

| 30–100 TPD | 400–800 m² | Same as above, with higher power/steam load for larger equipment |

- Environmental Note: A compact wastewater treatment system and dust collection unit (for bleaching earth) are required to meet local regulations.