Small Mini Sunflower Crude Palm Oil Refinery Machine in Zimbabwe

Small Mini Sunflower Crude Palm Oil Refinery Machine in Zimbabwe

QIE is a reliable manufacturer of vegetable oil machine including screw oil press/expeller, hydraulic cold expeller press, mechanical oil pressing machine, solvent oil extraction machine, and also customized cooking oil production line and crude oil refinery machine / equipment. Over 10 years of experience in equipment manufacturing and project constraction has proved our strong ability and great product quality.

Main Equipment for Vegetable Oil Manufacturing Plant

Oil Expeller Machine (Oil Squeezer): Includes traditional screw oil expeller and cold pressed hydraulic oil press machine. It can be widely applied to make oil from various oilseeds such as soybean, peanut, sunflower seeds, cottonseeds, sesame, rapeseed, linseed, neem, moringa seeds, pumpkin seed, flaxseed, grape seed, etc. (Capacity Range: 0.8ton~20tons/day small oil mill plant, medium-sized oil processing plant)

Oil Refinery Plant: The edible oil refining machine is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces. According to the refining scale, it is divided into 1-10ton/day Batch Type Small/Mini Oil Refinery Plant, 10-50 ton/day Semi-Continuous type Crude Oil Refinery Plant and 30-100T Continuous Vegetable Oil Refinery Plant.

Complete Oil Mill Plant: Offer customized both 1-20ton/day small oil production plant and 20-500ton/day cooking oil manufacturing plant. All our projects are designed based on different oilseed, capacity, and your specific situation and requirments. The main types of vegetable oil processing process includes oil squeezing/pressing, solvent extraction, pre-pressing & solvent extraction, oil refining, oil purification/clarification, oil fractionation.

___________________________________________________________________________________________________________

There are many different kinds of oil seeds for edible oil industry, QIE is here to offer tailor-made oil processing solutions specifically designed according to different characteristics of different oil seeds materials

Common Oilseeds: Flax seeds, tea seeds, palm kernels, copra, coconut, sunflower seeds, sesame seeds, soyabean, peanuts, cotton seeds, canola/rape seeds, mustard seeds, castor, hemp, black seed, groundnut, corn germ, rice bran, avocado and fish oil, etc

Main Sections and Process Design of Commercial Oil Mill Production Line

Oilseed Pretreatment: The oilseeds are procured, cleaned, flaked and cooked to ensure the oilseeds in the best condition prior topressing and extraction.

Mechanical Oil Milling Plant: It is a mechanical oil extracting method or seeds, nuts and vegetables, adopts oil pressing or expeller pressing/expelling process. The process is based on physics pressure which is featured of chemical-free. The process uses physical mechanical oil pressing method to exact oil out from the oil seeds with the main machines of seed cleaning machine, crushing machine, flaking machine, steam cooking machine, oil press machine and oil filter machine.

Solvent Extraction Plant: Adopts the working principle of solvent extracting technology to extract the oil from the oil seeds. There are batch oil extract machine (oil extractor) and continuous extractor (rotary extractor, loop type extractor, crawler type extractor). The capacity of edible oil solvent extraction plant ranges from 300kg to 100MT. The oil yield of solvent oil extraction plant can reach up to 99%, which is 60% higher than mechanical expeller oil processing. It is the best choice for commerical/industrial vegetable oil production line.

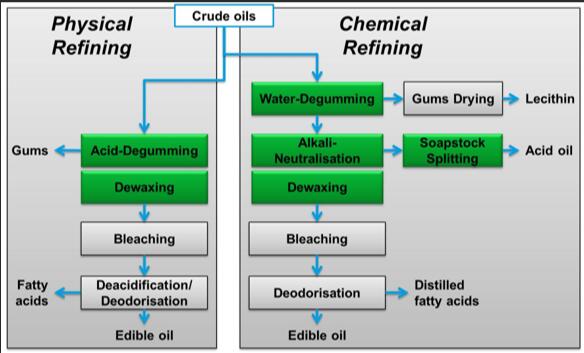

Edible Oil Refinery Plant: Both physical refinery and chemical refinery (batch& continuous) is available. Generally includes degumming, neutralization, bleaching and deodorizing/deodorization and winterization.

___________________________________________________________________________________________________________

Why Choose Us?

We are an international manufacturer, supplier and exporter of vegetable oil mill machinery and cooking oil mill plant. We can not only offer sunflower oil refinery machine, palm oil refinery machine, mini oil mill plant for starters to easily enter into the profitable oil industry , but also boast strong strengths to undertake customized complete turnkey projects of fully automatic oil mill plant and vegetable oil refining line.(Related other oil business post: Cold Press Oil Machine Sunflower Oil Extraction Machines in Zimbabwe>>)

Strong Project Engineering Capability: QIE is a large grain&oil machinery manufacturer integrating R&D, design, manufacturing, installation and after-sales service. The main technical team consists of professional technicians and process engineers. Thanks to the independent technology development department -- "Technology R&D Center", we can customize technical solutions according to customer needs.

Business Cooperation All Over the World: We have sales, service and engineering operations around the world, cooperate with more than 50 countries, while providing localized services.

Advanced Processing Equipment, Quality Assurance: Imported domestic and foreign CNC equipment with high processing precision. Each process in the production workshop is strictly trained according to standardized criteria, and the chief engineer personally manages the process during the production process to ensure product quality.

Successful Projects of Edible Oil Processing Plant

We are offering the factory price oil expeling machines and providing complete edible oil production line in many countries around the world, including Mexico, Panama, Pakistan, Thailand, Kazakhstan, Malaysia, Sri Lanka, Philippines, Uzbekistan, Chile, Brazil, Jamaica, Nigeria, Argentina, Ghana, Ethiopia, Russia, Australia, USA, Cameroon, Somalia, Uganda, UK, Moldova etc..If you have any other requirement on the palm oil refinery machine,just feel free to contact us!

___________________________________________________________________________________________________________

Edible Oil Refining Process

The edible oil refining equipment QIE Machinery provide is suitable for refining all kinds of crude vegetable edible oil, such as rice bran oil, peanut oil, soybean oil, sunflower oil, palm oil, palm kernel oil, cottonseed oil, olive oil, mustard oil, coconut oil, etc. In addition, it can also effectively refine the impurities contained in the edible animal oils, such as seal oil, fish oil, chicken oil, etc. The specific oil refining process for edible oil are detailed below.

- Degumming Stage

In the edible oil refining process, removing colloidal impurities from crude oil can be completed by physical, chemical or physicochemical methods, which is called degumming.

hydration degumming is a very important step. The amount, temperature and speed of water added with phosphoric acid are all important. Through the principle of glue flocculating when it meets water, the glue is precipitated.

- Deacidification Stage

The stage makes use the sodium hydroxide (NaOH) to neutralize free fatty acids in the crude edible oil, during which some soap will be produced and separated from the oil. Lye not only neutralizes free fatty acids, but also neutralizes excess phosphoric acid. In the process of batch and semi-continuous edible oil refining, we use the method of precipitation to separate soap feet. But in the full continuous refining process, we use a centrifuge to separate the soap, which is more efficient.

- Decolorization Stage

Since the crude oil contains pigment, the color of the oil will be darker. In order to improve the color of oil and obtain higher quality edible oil, we need to use media, such as activated clay, to absorb pigment, and then use vibration filter to separate the waste clay.

- Deodorization and Dehydration Stage

The smell of the crude oil is not very good, which will affect the storage and selling price of the oil. Therefore, we usually adopt direct steam to remove the smell of the crude oil. The oil also contains 0.5% water, which is removed by the high temperature in the deodorizer.

- Filtration Stage

After obtaining deodorant oil, we will use stainless steel precision filter (safety filter) to filter again to ensure the quality of oil.

- Dewaxing Stage

Some vegetable oils contain wax, such as sunflower oil, corn germ oil and rice bran oil all. So, dewaxing is necessary if you want to get first grade edible oil. This stage is optional according to the user's requirements.