Automatic Peanut Soybean Small Cold Groundnut Oil Processing Machine in Ethiopia

| Usage: | oil press production line |

|---|---|

| Type: | oil press production line |

| Automatic Grade: | Automatic |

| Production Capacity: | 100% |

| Model Number: | YL oil press machine |

| Voltage: | 380V |

Besides, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

Machine features:

1.Low consumption and high efficiency.

2.It contains a vacuum oil filter system and 2 oil filter barrels.

3.It is matched with one controlling cabinet box for controlling all working of the machines.

4.Small-land using: only 10-20square maters can meet the need for production.

5.It can save labor and cost: only 1 or 2people can finish the production.

Machine parameters:

| Model | SL-60A | SL-80A | SL-100A | SL-125A | SL-150A |

| Screw diameter(mm) | 60 | 80 | 100 | 125 | 150 |

| Capacity(kg/h) | 30-60 | 125-150 | 200-250 | 250-350 | 500-600 |

| Motor(kw) | 2.2 | 5.5 | 7.5 | 15 | 22 |

| weight (kg) | 220 | 700 | 1100 | 1400 | 1700 |

| Size(mm) | 1280*630* 1370 |

1480*630* 1570 |

2200*810* 1850 |

2200*1650* 1750 |

2600*2100* 1730 |

| Remark: SL-125A and SL-150A price are cold press type, including 2.5 meter feeding machine. | |||||

Details:

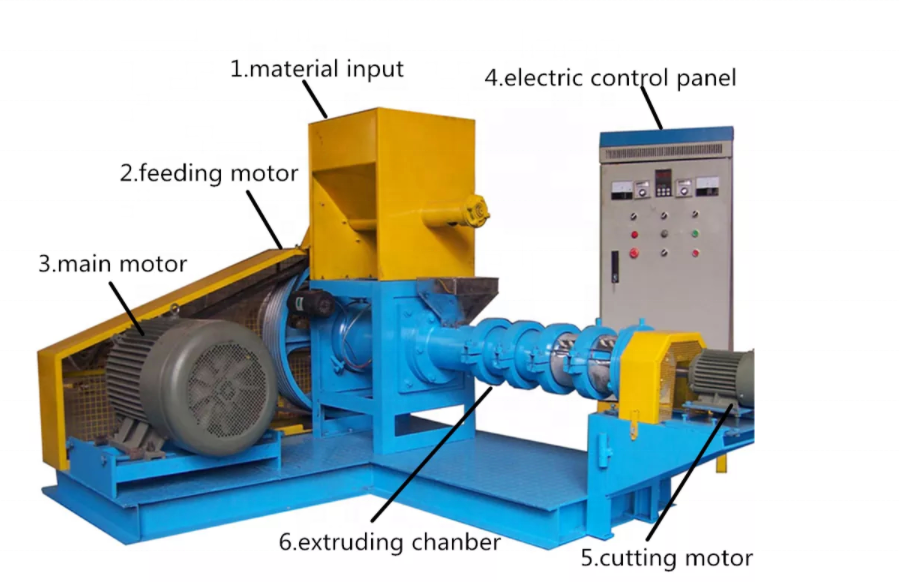

Soybean oil processing plant has two kinds, soybean oil pressing plant and soybean oil solvent extaction plant. Among the processing, soybean pretreatment is necessary, which can highly increase soybean oil yield. Here I mianly introduce how the soybean oil processing plant (pressing method) works.

| Type: | Soybean oil processing plant(pressing) |

| Processing Material: | soybean |

| Capacity: | 30-5000T/D |

| Application: | The processing of cleaning, crushing, softening, flaking, drying and so on by soybean pretreatment and soybean oil pressing machine. |

Peanut is one of common oil seeds. Many people extract oil from peanut only using a set of oil presser. But that will result a lot waste of peanut oil because of the high residual oil rate. In peanut oil processing plant, a series of machines will be used to process the peanut to best conditions and then be pressed.

Peanut oil processing plant includes peanut oil pretreatment machines and peanut oil press machine.

1. Husking machine: If peanut with shells, it should be husked first, or it will affect the oil quality and oil yield. In the above picture, the husking machine is used in large scale peanut oil processing plant, and the following is the small one.

2. Peanut kernel and shell separator: It is used to separating peanut kernel and peanut shell.

3. Cleaning machine: After separating kernel and shell, the peanut kernel should be first cleaned by vibrational cleaning sieve, magnetic separator and destoner. And this step is mainly to clean the big impurities, like the stone, big dust, iron, etc.

4. Crushing machine: This process is mainly to crush the peanut. As the peanut is too big to press, we need to crush the peanut to 6-8 pieces.

5. Flaking machine: After crushing, we need to flake the crushed peanut, which makes the cell wall of peanut broken. And we flake the peanut to 0.55mm thickness. Then it is useful for the oil extracting.

6. Cooking machine: After the flaker, we need to cook the peanut, controling the moisture is at 5-7% and the temperature is about 110 -115 degree.

7. Pressing machine: After all the pretreatment procedures, the peanut can be pressed by peanut oil press machine to get about 76% peanut oil or more, or extract oil by cooking oil solvent extraction plant.