Sunflower Oil Making Machine at Factory Price

How to Make Sunflower Oil?

Sunflower oil is a kind of high-quality edible oil. it is rich essential fatty acids for the human body, unsaturated fatty acids up to 85 to 90 percent, and the content of linoleic acid is 65%, which has high nutritional value. but sunflower oil contains a small amount of wax (usually 0.06% to 0.10% of crude oil). The presence of wax not only affects the transparency and taste of sunflower oil, but also smokes and produces a choking smell during cooking, which affects human health. When the temperature is higher than 40℃, the wax in sunflower oil has weak polarity and dissolves in sunflower oil. As the temperature drops, especially when the temperature is lower than 30°C, the wax crystallizes and forms relatively stable crystals. After a period of time at this low temperature, the wax crystals condense into larger grains. As the storage time increases, the wax crystal grains gradually increase and become a suspension. at this time, the oil becomes suspension. The transparency of sunflower oil decreases. The global consumption of sunflower oil is ranked 4th after palm oil, soybean oil and rapeseed oil. Sunflower oil is mainly used in food and cosmetic sector. So, how to turn the sunflower seeds into sunflower oil or cooking sunflower oil? One of the most commonly used method for sunflower oil making is mechanical pressing with screw oil press machine. This methods is relatively simple, features low cost and doesn't require chemical solvents, so it is widely adopted by many medium and small scale cooking oil production line. According to the oil production process, sunflower oil processing equipment including cleaning sieve, destoning machine, flaker, cooker, oil filter machine, oil filter machine, edible oil refining machine and more.

Our Company is leading oil processing machine manuafacturer and supplier. We offer various sunflower oil making machine types at factor price. Sunflower oil making business is profitable around the world, especially in China, India, South Africa, Tanzania, Ukraine, Kazakhstan, Brazil, and more. More and more people can't find out where to buy the most suitable and cost-effective sunflower oil making machine for their business. QIE is definitely your reliable supplier. (Read more about Sunflower Oil Manufacturing Cost >>)

Sunflower Oil Making Machine Types and Price

In order to better meet customers' sunflower oil processing requirements, we develops three types of sunflower oil making machines for your choice.

Small Screw Sunflower Oil Making Machine

- Single Screw Oil Making Machine

- Automatic Oil Making Machine with Filters (Air Pressure or Vacuum Filter)

- Auto-temperature Oil Making Machine

Automatic Sunflower Oil Making Machine

The Sunflower Oil Press Machine designed by QIE makes use of the mechanical force to squeeze oil out from the seeds. During the process of oil pressing, there are no involvement of addition of any addictive. As a result, the oil is natural, healthy and full of nutrition.

Sunflower Oil Making Machine advantages

- The sunflower oil machine has high oil extraction rate. ...

- The sunflower oil making machine is applicable to a wide range of raw oil crops, including palm, soybeans, coconut, walnuts, peanuts, pine nuts, sunflower seeds, almonds, etc.

- High efficiency is also its outstanding features.

Sunflower Oil Making Machine at Factory Price

From the outside appearances, the structure of auto-temperature and automatic sunflower oil making machine are more complicated. The automatic type is equipped with air pressure filters and electric control cabinet. And, the auto-temperature oil press is also designed with electric control cabinet, but no filters. All the designs is for the highest oil extracting output based on the actual oil production operational requirements. You can choose the best one according to your specific requirements. And, all of these machine are very wonderful choice for small, medium or large scale oil making plant.(Related Post: Sunflower Oil Production Business Plan >> )

Single Screw Oil Machine

Autom-Temperature Oil Machine

Automatic Oil Machine with Air Pressure Filters

Sunflower Oil Refining and Dewaxing Machine

Just like other vegetable oil processing, sunflower oil production also needs several process to get high quality oil, including seeds cleaning, seeds cooking, seeds flaking and more. It is also important to note that the oil extracted by mechanical pressing or solvent extraction is crude oil, so Edible Oil Filter Machine and Sunflower Oil Refinery Machine is recommended to produce high quality sunflower oil.

Small Oil Refinery Unit for Sunflowr Oil Making

Since sunflower seed oil contains a small amount of wax, the existence of wax in sunflower oil not only affects the transparency and taste of the oil, but also causes bad smell when cooking and affects human health. Sunflower oil dewaxing process can effectively remove the wax in sunflower oil.(You may also interested: Turkey Small Scale Sunflower Oil Press Price South Africa >>)

1. Dewaxing process

Oil to be dewaxed → Cooling and Crystallization → Maturation → Filtration(Wax paste) → Finished oil

2.Main equipment for dewaxing process

The dewaxing equipment mainly includes refrigeration units, heat exchanger, crystallizing and maturing tanks, and horizontal leaf filter.

Sunflower Oil Dewaxing

The extracted sunflower oil should be processed further to make it an edible product. Edible oils are refined to improve their flavor, odor, color and stability. The refining process will remove contaminants such as phosphatides, free fatty acids and pro-oxidants. Apart from the normal refining steps, some oils and fats need further processing. They are winterized and modified to alter their melting characteristics.

Sunflower Oil presents an un-pleasant turbidity at low temperature. This can be removed by eliminating components like waxes which solidify at low temperature through the process known as Dewaxing. The process of dewaxing is carried out especially for Sunflower Oil to remove those waxes.

The by-products of dewaxing can be further processed to create value-added products or reduce costs.

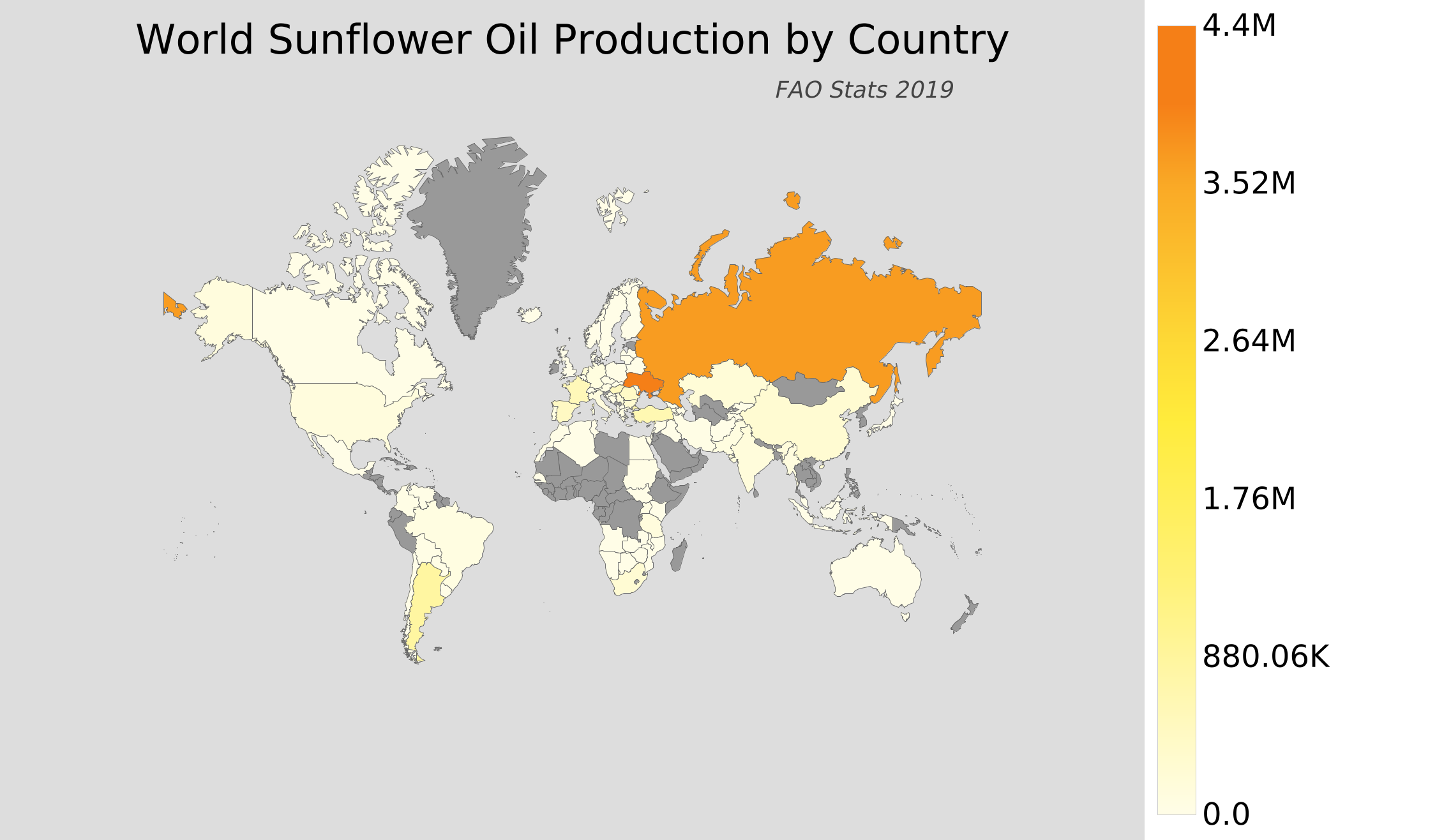

World Sunflower Oil Production by Country

- Worldwide 15,848,036 tonnes of sunflower oil is produced per year.

- Ukraine is the largest sunflower oil producer in the world with 4,400,324 tonnes production per year.

- Russian Federation comes second with 4,063,080 tonnes yearly production.

- Ukraine and Russian Federation produce together more than 50 % of world's total sunflower oil.

- With 931,700 tonnes of production per year, Argentina is the third largest producer of sunflower oil.

- United Kingdom, with 0 tonnes of production per year is ranked at 82.

| Country | Production (Tons) | Production per Person (Kg) | |

|---|---|---|---|

|

Ukraine | 4,400,324 | 104.115 |

|

Russian Federation | 4,063,080 | 27.663 |

|

Argentina | 931,700 | 20.94 |

|

Turkey | 721,882 | 8.933 |

|

France | 632,900 | 9.405 |

|

Hungary | 566,100 | 57.937 |

|

Spain | 503,500 | 10.791 |

|

Romania | 454,576 | 23.283 |

|

Bulgaria | 318,300 | 45.149 |

|

China | 299,848 | 0.215 |

|

South Africa | 280,682 | 4.862 |

|

The Netherlands | 240,500 | 13.941 |

Ways To Make Your Own Sunflower Oil

Typically, most salad and cooking oils you purchase from your local grocery stores are extracted using solvents or pressure, or both. However, if you want to make your own sunflower at home, these solvents are best avoided.

Instead, consider investing in a high-quality oil press to have a more wholesome fresher end product. So, on that listed below are a few steps to make your own sunflower oil the natural way!

Step 1: Clean The Sunflower Oil And Blend Them

To make your own sunflower oil, you must first clean the sunflower seeds and blend them in a blender. After blending the seeds into a thick paste, add two tablespoons of water and continue blending for a couple of minutes. When you see a layer of oil form on the top of the mixture, stop blending.

Step 2: Collect The Oil In A Bowl

The next step is to take out the paste and residual oil from the blender and transfer it into a large bowl. Then, use your hands to squeeze the oil from the paste into a separate bowl. Continue this step until all of the oil is extracted from the paste.

Step 3: Sift The Oil

The last step involved in the oil-making process is to filter it with a fine sift to remove any large sediments. You can heat the oil in your microwave or in a saucepan to have a clear-looking oil. Lastly, store your homemade sunflower oil into a mason jar or oil bottle, and you're done!

Wrapping Up

Congratulation! You've now learned how to make your own sunflower oil at home. Of course, you won't get the results you're after if you haven't made any oil at home before. However, using homemade sunflower oil, whether for cooking or dressing salads, is still better than consuming packaged oil. So, go ahead and make some today!