Sunflower Oil Production Line in Argentina

Sunflower oil is a kind of high nutritional edible oil with large market demand and broad investment prospects. The sunflower oil production line adopts advanced physical pressing technology and refining equipment and makes the first-grade sunflower oil, which can be directly sold. The processing steps of the sunflower oil production line mainly include roasting, pressing, filtering, refining and filling. The production line has a high degree of automation, various outputs, and high oil quality. The sunflower oil processing machine is suitable for small and medium-sized oil extraction factories or workshops.

Set Up Large Scale Sunflower Oil Production Line in Argentina

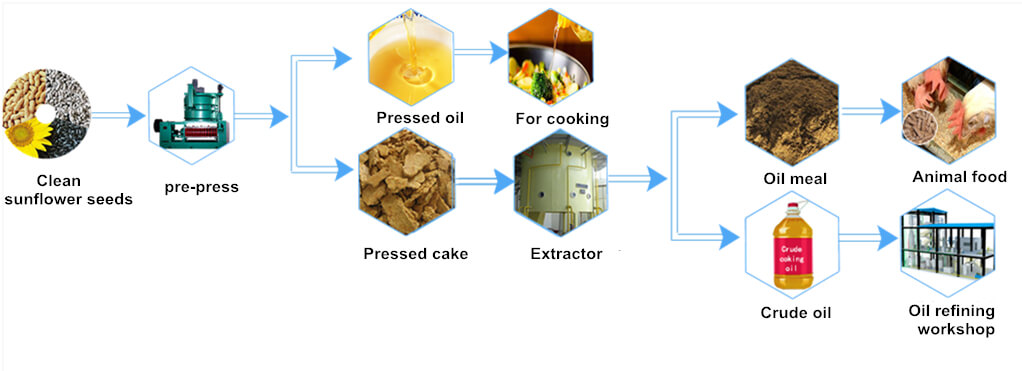

Large sunflower oil production factory need a complete sunflower oil production line, which has four parts: 1. Sunflower seeds pretreatment; 2. Sunflower oil extraction section; 3. Sunflower oil refining section.

Sunflower seeds pretreatment section

Sunflower seeds preparation is through a series of machines to deal with sunflower seeds in order to adjust the shape, temperature and humidity of sunflower seeds to extract sunflower oil easily.

In the pretreatment section, we use magnetic separators, vibrating cleaning sieves, shellers, kernel-shell separating sieves, germ rolling machines and transfer equipment.

In this stage, we first use magnetic separator and vibrating cleaning sieve to remove impurities such as metal and branches and leaves from sunflower seeds. These impurities are not conducive to oil production on the one hand, and can affect the normal operation of the oil press on the other. After obtaining clean sunflower seeds, we use a sheller and a kernel-shell separating sieve to obtain clean sunflower kernels. After that, we will use the germ rolling machine to press the sunflower seeds into thin slices to improve the oil yield by increasing the contact area between the sunflower seeds and the oil press.

Sunflower oil extraction section

As one of four major edible oil in the world, sunflower oil is an advanced nutritional oil because it contains a lot of essential unsaturated fatty acids such as linoleic acid, which can promote the regeneration and growth of human cells. Sunflower oil can be produced in two ways, includes pressing method and solvent extraction method. Different methods owns different advantages. Sunflower oil producers can choose one according to the processing capacity of raw material and processing needs in reality.

Sunflower oil extraction by pressing method:

Step 1: We can use cleaning equipment ( vibrating screen&destoner ) to remove impurities in sunflower seeds to ensure the quality of oil and the service life of equipment;

Step 2: The clean sunflower seeds would be transported to cracker to crack the sunflower seeds, which prepared the nest step.

Step 3: The step is to use kernel husk separator to separate husk from the kernels of sunflower seeds.

Step 4: The step is to use cooker to adjust the temperature and humidity of sunflower seeds, so that the best conditions is ready for pressing sunflower seeds.

Step 5: After completing the above steps, the cooking oil press is used to extract sunflower oil by physical extrusion.

Step 6: Finally, we need to use a filter to remove impurities in the oil.

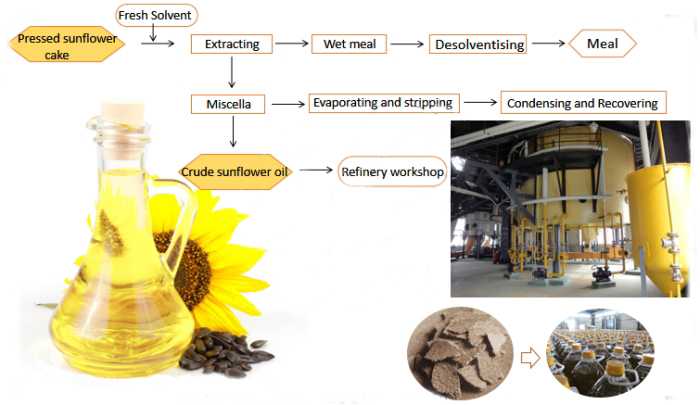

Sunflower oil extraction by solvent extraction method:

If your raw material is sunflower seed oil cake, you can directly carry out the solvent extraction process. If your raw material is sunflower seed, then you need cleaning, cracking, shelling and cooking and pressing or pre-pressing to get sunflower oil cake.

Step1: The solvent extraction method applies the principle of extraction, selecting a certain organic solvent that can dissolve the oil, and makes it contact with the pretreated oil by soaking or spraying, so that the oil in the oil is dissolved.

Step2: The wet meal is evaporated to remove the solvent and water in it in order to get the dry meal and recover the solvent.

Step3: The mixed oil obtained from solvent extraction need to be handled in mixed oil evaporation system, which uses the different boiling points of the solvent and oil, the mixed oil is evaporated and stripped, then the solvent is evaporated, the oil is left.

Step4: Finally, the evaporated solvent is recovered by condenser and recovery system from D.T.D.C system and mixed oil evaporation and stripping machine.

Working principle of sunflower oil solvent extraction plant:

By taking advantage of oil fat and n-hexane can dissolve with each other, use the n-hexane to react with processed sunflower seeds or pressed sunflower seed oil cakes. Then we’ll get wet meals and mixed oil, also called miscella.The mixed oil is pumped in to evaporation system to get crude oil and solvent gas. Wet meals will be delivered into Desolventizing Toasting Drying and Cooling tower system(D.T.D.C system) to get dry meals and solvent gas. Then by condensing, the n-hexane can be recycled to reduce solvent loss.

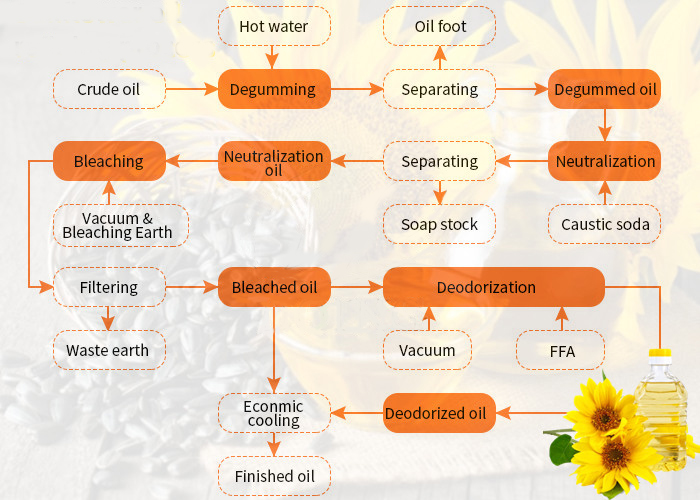

Sunflower oil refining section

Sunflower oil refinery plant is to remove harmful impuries and useless substance, such as protein, phospholipid, pigment, moisture, wax and other impurities. And then the refined sunflower oil can reach the standard of food and storage.

Main process of sunflower oil refining:

The first step in refining involves the degumming of the Crude Sunflower Oil. Degumming is done for the treatment of the Phosphatides & other impurities. Technically, Degumming is the purification of the sunflower oil which normally contains impurities in colloidal state& dissolve in them.

While doing degumming of crude sunflower oil process, we remove hydratable and non hydratable gums by using Salt water, dilute acid such as phosphoric acid / Citric acid / oxalic acid / tartaric acid.

The hydratable gums are insoluble in oil and can remove using water by centrifugation method. The non hydratable gums are soluble in oil and can remove using acid by making them hydratable or insoluble in oil.

Non – Hydratable gums are Phosphatidylethanolamine and magnesium & calcium salt of Phosphatidic acid.

QIE Group follows different type of degumming processes like Water Degumming/Acid Degumming/ Enzymatic Degumming. These processes are being selected based on methods of processing, chemicals used and the content of phosphatides in the crude vegetable oil.

Neutralization section of sunflower oil refining process:

Neutralization of degummed oil involves the reaction between free fatty acid and alkali solution such as sodium hydroxide /Potassium hydroxide. The result is formation of Sodium soap takes place and settled in the neutralizer machine and removed as a soap stock.

Bleaching Section of Sunflower Oil Refining Process:

The bleaching of Sunflower oil is an essential part of the sunflower oil refining process after degumming / Neutralization. Originally the bleaching was only used to remove the color. Now a days bleaching process are used to remove coloring pigments as well as some undesirable impurities which are harmful to human consumption.

The Bleaching step is normally carried out after alkaline refining / Neutralization or Degumming. In this process we mainly remove the coloring pigments like carotenoids & chlorophyll, some oxidative products, soap traces, metals and residual phosphatides. All these compounds have adverse effect on quality and shelf life of oil, and therefore be needed to remove to make the product commercially attractive and long shelf life.

Dewaxing Section of Sunflower Oil Refining Process:

Dewaxing of the Sunflower is required in order to reduce the cloud point of the refined sunflower oil. The small quantities of solids from oil are removed that would normally cause cloudiness of the oil. These substances can be saturated glycerides or waxes. Waxes are esters for fatty alcohol and fatty acid, which have a very low solubility in oil. There quantity is different in different oils.

Generally, varies in between 48-2000 ppm.

In order to obtain oil with good cold stability, the wax content needs to minimize with respect to the atmospheric temperature. In this process cooling rate & agitation are carefully controlled to promote the formation of nuclei that will serve as the sites for crystal growth.

In Winter season when the temperature is low, waxes appears in the oil causes haziness.Winterization or dewaxing of Sunflower is necessary to produce salad oil.

Deodorization Section of Sunflower Oil Refining Process:

The Deodorization or deacidification is actually stripping process in which a little amount of low pressure steam passes through hot oil. In Sunflower Oil Deodorization process various types of volatile molecule and odoriferous compound removed. This process carried out at very high temperature more than 200 degrees Celsius.

In Deodorisation process we also do thermal destruction of flavor and heat sensitive coloring pigments. A little amount of Coloring pigments is removed. Time play important role in this process, deodorization is the high temperature and high vacuum steam distillation process. It is used to remove high volatile and odoriferous material present in bleached oil.

If the Deodorization time is too short than some odoriferous compounds will remain in deodorized oil and resulting is the development of flavor again during storage of oil. if the Deodorization time is too long than oil can be polymerized due to high temperature and high vacuum.

Set Up Small Scale Sunflower Oil Production Line in Argentina

- Production Output: 1-20ton/day

- Main Equipment: Cleaning/screening machine, seeds cooker, oil expeller, oil filter press and conveyors.

This sunflower oil manufacturing unit is effective, automated and affordable which makes it ideal choice for small scale sunflower oil factory. It is capable of continuous cooking oil processing plant.

Small Scale Sunflower Oil Processing Steps

- Step 1, Rosting (Heat Treatment)

Heat treatment is one of the most important processes in the process of extracting oils and fats. Materials that are pressed after roasting are called hot pressing, and those that are not subjected to heat treatment are called cold pressing. Sunflower seeds are mainly hot pressed, and the effect of heat treatment has a direct impact on the smooth progress of the entire oil production process, the level of oil yield, and the quality of oil products and cakes. It is best to choose the oil sunflower seeds that are one month after harvesting. The hot pressed oil sunflower can be pressed evenly when it reaches 70% or 80% roasting degree, with the highest oil yield and very fragrant oil.

- Step 2, Pressing

The round bar of the sunflower oil press in the sunflower oil production plant has a zigzag curve and a conical surface. When the oil sunflower is pressed, it is pushed and squeezed by the squeezing snail, so that the inner wall space of the squeezing snail and the squeezing cage is continuously reduced. The blanks are alternately pressed and loosened here, and the structure of the blanks is continuously adjusted to be evenly turned, so that the unpressed oil or the blanks with less oil have more chances to be fully pressed.

- Step 3, Filtering

The sunflower oil squeezed by the automatic sunflower oil press contains a certain amount of oil residue. In order to improve its purity, the sunflower oil machine is equipped with two vacuum oil filter barrels. The filtered oil has less oil foam, and it is clear and translucent, and the oil fragrance is overflowing.

- Step 4, filling

Fully automatic sunflower oil filling machines ensure efficient and precise filling. The automatic oil packaging machine meets food processing safety standards and saves great labor.

How do you start a sunflower oil plant?

1. When investing in a sunflower oil processing project, no matter the scale of the project, it is recommended to find a powerful sunflower oil production plant manufacturer for assistance. Taize has rich experience in the manufacture of edible oil processing machinery and a large number of transaction cases, and is a powerful assistant for the majority of users to invest in the construction of oil plants. We provide technicians for process design, machine installation, commissioning, and personnel training. Our oil processing machines have been installed in a large number of countries and brought customers great benefits.

2. In terms of investment scale, for investors with limited conditions and low budgets, they can start with small investments, such as opening an oil mill plant. It has more flexible processing.

3. To invest in a sunflower seed oil production plant, the first is the choice of a sunflower oil press. For sunflower oil pressing, most users will choose a screw press.

4. In order for the sunflower oil processed by the user to have a wider market, it is recommended to set a refining oil process, which can refine the pressed sunflower oil to the first-class sunflower oil standard.

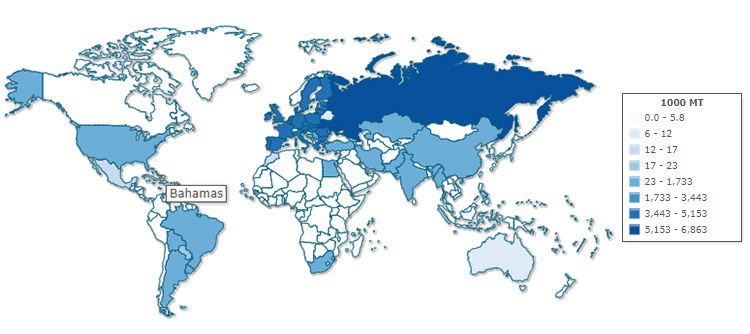

Market of Sunflower Oil Industry

The TOP producers of sunflower oil includes Ukraine, Russian, Argentina, Turkey, Ethiopia, South Africa, Serbia, Kazakhstan, United States, Myanmar, Moldova, Pakistan, and India.

Sunflower oil production accounts for about 80% of the sunflower crop and this paves the way for huge International market dealing with the production process. According to the IRUE National center of marketing and price study’s reports, Russian Federation is the leading manufacturer of sunflower oil contributing to 22.4% of the total production with just 21.8% consumption which favors active export of the oil produced to abroad. While Argentina is the leading exporter with a good share of about 35% in International sunflower oil production market.

Ukraine with a share of 18.4% in the International market of production and insignificant consumption also makes its place amongst the most significant exporters of sunflower oil. While, the story takes the opposite turn in Turkey and European Union(EU), where internal consumption of sunflower oil is far more than the production, thereby giving rise to the need of huge imports. Although EU’s share in production is 36.5%, its excess consumption of 41.8% makes it fall into the category of importers.