Palm oil press processing machine line plant ghana

Palm oil press processing machine line plant

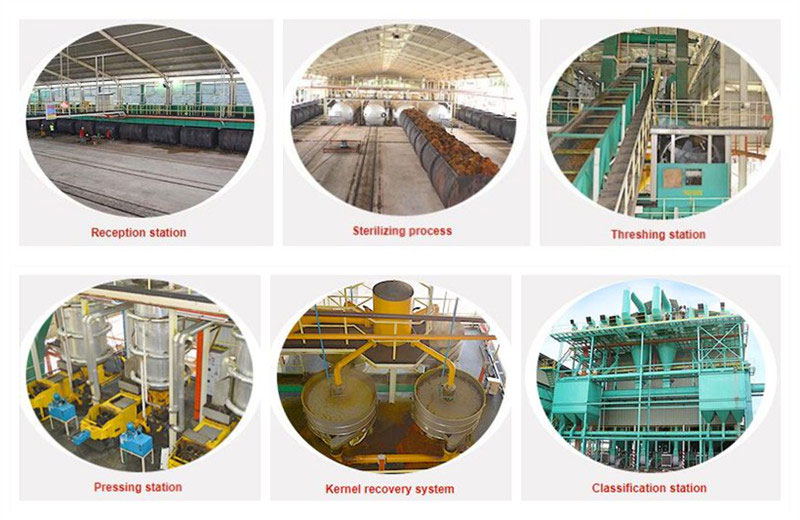

FFB Process: After transporting the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm fruit cage. After separating palm fruits and palm bunch by thresher,Palm fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel. After pressing,we can get palm cake and palm nut. Pam nuts will be conveyed to palm recovery system to get palm kernels, fiber and palm shell. Palm cake will be conveyed to boiler room as fuel. After filtering,centrifuging, and vacuum drying, we can get crude palm oi (CPO), the CPO can be sold directly or used for further processing. The sewage from all the plant will be processed by sewage treatment to reach discharge standard. Sludge can be used for fertilizer in palm plantation. All the process cycle features with short operation cycle, high automaticity, energy conservation and environmental protection.

Palm oil press processing machine line plant

1 Compact and strong structure, and easy operation.

2 The automatic control system which can adjust barrel pressure.

3 High oil pressing efficiency, and residual oil in cake is less than 8%.

4 Low crushing efficiency for palm nut.

5 Invest is small, quick gains.

Specification

| Capacity : | 15 TPH | Oil extraction rates : | 20~22% |

| Oil content in FFB : | ≥24% | Kernel content in FFB: | 4% |

| shell content in FFB : | ≥6~7% | Fibre content in FFB : | 12~15% |

| Empty bunch content in FFB: | 23% | Press cake proportion in FFB: | 24 % |

| Oil content in empty bunch | 5 % | Moisture in empty bunch : | 63 % |

| Solid phase in empty bunch: | 32% | Oil content in press cake | 6 % |

| Water content in press cake : | 40 % | Solid phase in press cake : | 54 % |

| Oil content in nut: | 0.08 % | Oil content in wet meter heavy phase: | 1% |

| Oil content on meter solid: | 3.5% | Oil content in final effluent: | 0.6% |

| Fruit in empty bunch: | 0.05% | Total in losses: | 1.5% |

| Extraction efficiency: | 93% | Kernel Recovery efficiency: | 93% |

| Kernel in empty bunches: | 0.05% | Kernel content in cyclone fiber: | 0.15% |

| Kernel content in LTDS: | 0.15% | Kernel content in dry shell | 2% |

| Kernel content in wet shell | 2.5% |

Service:

1.Design according to your special requirement.

2.Free repair within 1 year.

3.Engineer could work to your country

4.we are responsible for installation, test running and training local workers for you.

Our products with the domestically level in both quality and performance not only have a market in china, but also are exported all around the world include Asia, Europe, Africa, America, Middle East and other 50 countries and regions. Our engineers have many years experience of grain processing, as we have successfully completed 280 domestic and international projects. Our company provides processing technology solutions, designs, supplies equipment, installation and commissioning personnel, operator training and has excellent after sale services for the support of all our customers. Typical plant capacity range from 10- 800 MT per 24 hours.

FAQ

Q1: Are you a trading company or a manufacturer?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q2: How can I get to your company?

A: You can get a flight to Zhengzhou Xinzheng International Airport,or you can go here by train to Zhengzhou Railway Station/Zhengzhou East Railway Station

Q3.What's the Payment?

A:We accept T/T, Western Union , Alibaba Trade assurance. Especially Alibaba Trade assurance. Which is guaranteed by Alibaba, it is more safe and effective.

Q4: Will you send engineers to install the plant?

A:we send engineers to your place for guiding installation. Engineers are responsible for guide installation, test running and training.

Q5: Can you show how the machine works?

A: Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better.