Coconut Oil Production Line in Sri Lanka

Coconut oil (or coconut fat) is an edible oil derived from the meat of the coconut palm fruit. Coconut oil is a white solid fat below around 25 °C (77 °F), and a clear thin liquid oil at higher temperatures. Unrefined varieties have a distinct coconut aroma. Coconut oil is used as a food oil, and in industrial applications for cosmetics and detergent production. The oil is rich in medium-chain fatty acids.

Due to its high levels of saturated fat, numerous health authorities recommend limiting its consumption as a food.

Coconut oil is widely used for cooking and baking due to its high smoke point and distinct flavor.

Make Coconut Oil with Cheap Dried Copra

The crude oil is different compared to existing oils in the market like virgin or extra virgin. The three methods used to dry copra include the following: sun, smoke or kiln or sometimes using the three methods to get the dried coconut meat of copra. Solvent and increased heat are needed to extract more oil and in getting rid of impurities by filtration while bleaching agent is added for colorless, odorless and tasteless oil. In large scale industrial coconut mill, the oil is bleached and deodorized. During extraction, more heat (90C/194F) is needed, the oil produced in the process is brown in color, therefore, it is bleached to make it whiter. To make the oil consumable, reining part is necessary to omit free fatty acids between 3% and above using weak caustic soda, oil is passed through steam caused by the heat of about 230C/446F hence the style came to be known as poor man’s oil in ancient days.

Small Scale Coconut Oil Production Line

Small-scale coconut oil production lines are compact, affordable systems using either screw expellers (for copra) or cold presses/centrifuges (for virgin oil).

Small-scale lines generally process between 1 to 20 tons of raw material per day. The most popular equipment choice for this scale is the expeller press due to its efficiency and lack of chemicals.

Dry Process (for Copra/RBD Oil)

This process is more common for standard cooking oil and uses dried coconut meat (copra).

Cleaning & Drying: Remove shell/skin, then dry fresh coconut into copra (7-10% moisture).

Crushing: Crush copra into small, uniform pieces.

Cooking (Softening): Steam/cook crushed pieces to adjust moisture and temperature for better oil release.

Pressing (Pre-press & Second Press): Use screw or hydraulic presses to extract crude oil, leaving oil in the cake.

Extraction (Optional): Solvent extraction can get more oil from the cake.

Filtration: Filter the crude oil.

Refining: Degumming (phosphoric acid), neutralizing (caustic soda), bleaching (bleach earth), and deodorizing to create RBD oil.

Small Scale Considerations

Equipment: Small lines use integrated screw presses, hydraulic presses, or dedicated VCO machines.

Scale: Can range from 1-20 TPD (tons per day).

Choice: Dry process for industrial/cooking oil; wet process for premium health/cosmetic VC

Large Scale Coconut Oil Production Line

Large-scale coconut oil production lines are primarily designed for high-capacity, continuous operation (often 50–600 tons per day) and are categorized by the method used to process the coconut kernel.

Production Line Types

Virgin Coconut Oil (VCO) Line: Utilizes wet processing to extract oil from fresh meat without high heat or chemicals.

Refined (RBD) Coconut Oil Line: Uses dry processing with copra. The resulting crude oil must be Refined, Bleached, and Deodorized (RBD) for consumption.

Dry Process (Copra-based RBD Oil)

This is the most common industrial method, producing Refined, Bleached, and Deodorized (RBD) oil from dried coconut meat (copra).

Pretreatment

Mature coconuts are dehusked and deshelled. The meat is dried (to 6–10% moisture) using rotary or kiln dryers to create copra.

Cleaning & Crushing: Copra passes through magnetic separators to remove metal and toothed roll crushers to create uniform particles for extraction.

Cooking: Crushed copra is heated in vertical steam cookers (approx. 100–115°C) to adjust moisture and rupture fat cells for better oil release.

Extraction

Mechanical Pressing: A "twice-pressing" technique is used; the first pass extracts ~70% of the oil, and a second pass reduces residual oil in the cake to 5–8%. Due to the distinct material properties of copra from common oil materials, if we process it in conventional way, there may result in no feed, no cake out or there is any oil squeezed out at the pressing cage, so the pressing bar clearance needs to be adjusted. When pressing copra, the gap between the pressing bars must be small.

Solvent Extraction: Copra oil solvent extraction is a high-efficiency industrial process used to maximize oil yield from dried coconut meat. While mechanical pressing typically leaves 5–8% residual oil in the cake, solvent extraction can reduce this to less than 0.8–1.5%.

Pre-press Solvent Extraction: The most common method for copra (which has a high initial fat content of 60–70%). Copra is first mechanically pressed to reduce oil content to roughly 16–20%, and the resulting "pre-press cake" is then treated with solvent.

Full Solvent Extraction: Rare for raw copra due to its high fat content; more often used for lower-fat materials or as a secondary stage to recover oil from already processed meal.

Core Stages of Solvent Extraction

1.Preparation (Flaking): Dried copra or pre-pressed cake is crushed into 2–3 mm particles and then flaked into thin layers to increase the surface area for the solvent to penetrate.

2.Solvent Contact: The flakes are placed in an extractor (rto-cell or basket type) where hexane is circulated. Hexane dissolves the oil, creating a mixture called miscella.

3.Desolventizing (DT): The defatted meal (now called "copra meal") is heated in a Desolventizer-Toaster (DT) to evaporate and recover the solvent for reuse.

4.Oil Recovery (Stripping): The miscella is heated in evaporators and stripping columns to boil off the hexane, leaving behind crude coconut oil.

5.Solvent Condensation: The hexane vapors from the DT and stripping units are condensed and separated from water to be recycled back into the system.

Refining (Physical or Chemical)

Crude coconut oil contains impurities (gums, free fatty acids, pigments, odors) that must be removed for commercial use. Large-scale plants combine physical and chemical refining for efficiency.

Degumming:

Crude oil is pumped into a degumming tank; dilute phosphoric acid (0.1–0.3%) is added and stirred at 70–80°C. Phospholipids (gums) hydrate and precipitate.

The mixture is centrifuged in a disc stack centrifuge to separate gum sludge (used as fertilizer or animal feed additive).

Neutralization (Deacidification):

Degummed oil is mixed with dilute sodium hydroxide (NaOH) solution in a neutralization reactor. Free fatty acids react with NaOH to form soap stock, which is separated by centrifugation.

Soap stock is processed into industrial soap or biodiesel feedstock.

Bleaching:

Neutralized oil is pumped into a continuous bleaching tower filled with activated clay and activated carbon. Under vacuum conditions (≤ 5 kPa) and 100–110°C, adsorbents remove pigments, residual soap, and trace metals.

Spent clay is regenerated or disposed of as non-hazardous waste.

Deodorization:

Bleached oil enters a high-vacuum deodorization tower (vacuum ≤ 0.5 kPa) and is heated to 220–240°C. Live steam is injected to strip volatile compounds (free fatty acids, aldehydes, ketones) that cause off-flavors.

This step produces odorless, pale yellow refined coconut oil.

Winterization (Optional for Cold-Climate Markets):

Deodorized oil is cooled to 10–15°C in a crystallization tank and stirred slowly for 8–12 hours. High-melting-point triglycerides crystallize and are filtered out using a plate-and-frame filter.

The resulting oil remains liquid at 10°C, suitable for cold-region consumption.

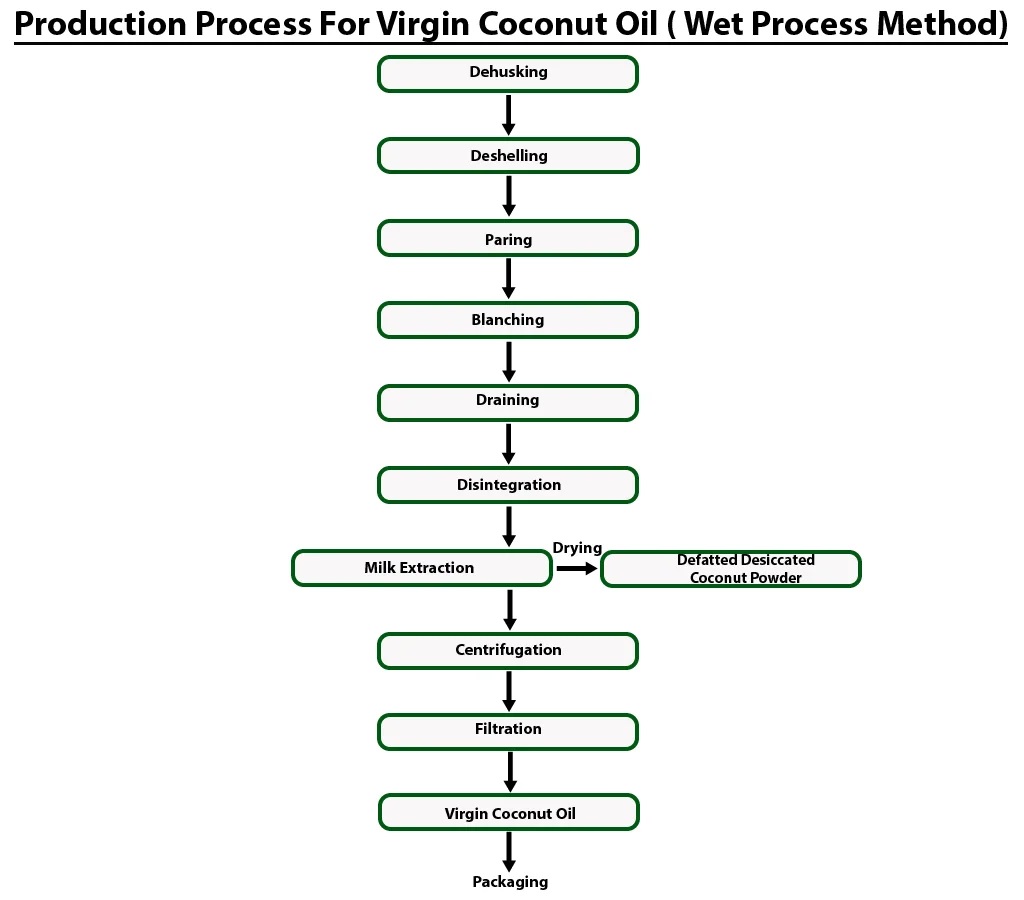

Wet Processing (Virgin Coconut Oil - VCO)

VCO is produced from fresh coconut meat without chemical refining to preserve natural antioxidants and aroma.

Milk Extraction: Fresh meat is grated and pressed (sometimes with added water) to produce coconut milk.

Separation Techniques:

Centrifugation: A high-speed centrifuge (up to 12,000 RPM) quickly separates oil from water and solids. This is the most efficient modern method, yielding up to 92% recovery.

Cold Pressing: Fresh meat is dried briefly and then pressed at low temperatures (below 60°C) to maintain nutrients.

Fermentation: The milk sits for 24–48 hours until natural or induced bacteria separate the oil layer.

Chilling & Thawing: Freezing the milk and then thawing it breaks the emulsion to release oil.

Finishing: The oil is filtered and may undergo a low-temperature vacuum drying step to reduce moisture below 0.5%, extending shelf life.

Coconut oil is a cornerstone of Sri Lanka’s agriculture and economy, deeply rooted in its culture, diet, and exports, with products ranging from traditional white coconut oil to premium virgin coconut oil (VCO). Sri Lanka’s coconut oil production centers on two primary types, with a mix of small-scale traditional mills and large-scale industrial lines. The future of Sri Lanka’s coconut oil industry will be shaped by premiumization, sustainability, tech-driven production, and export-focused value addition, with VCO and organic lines leading growth through 2030.