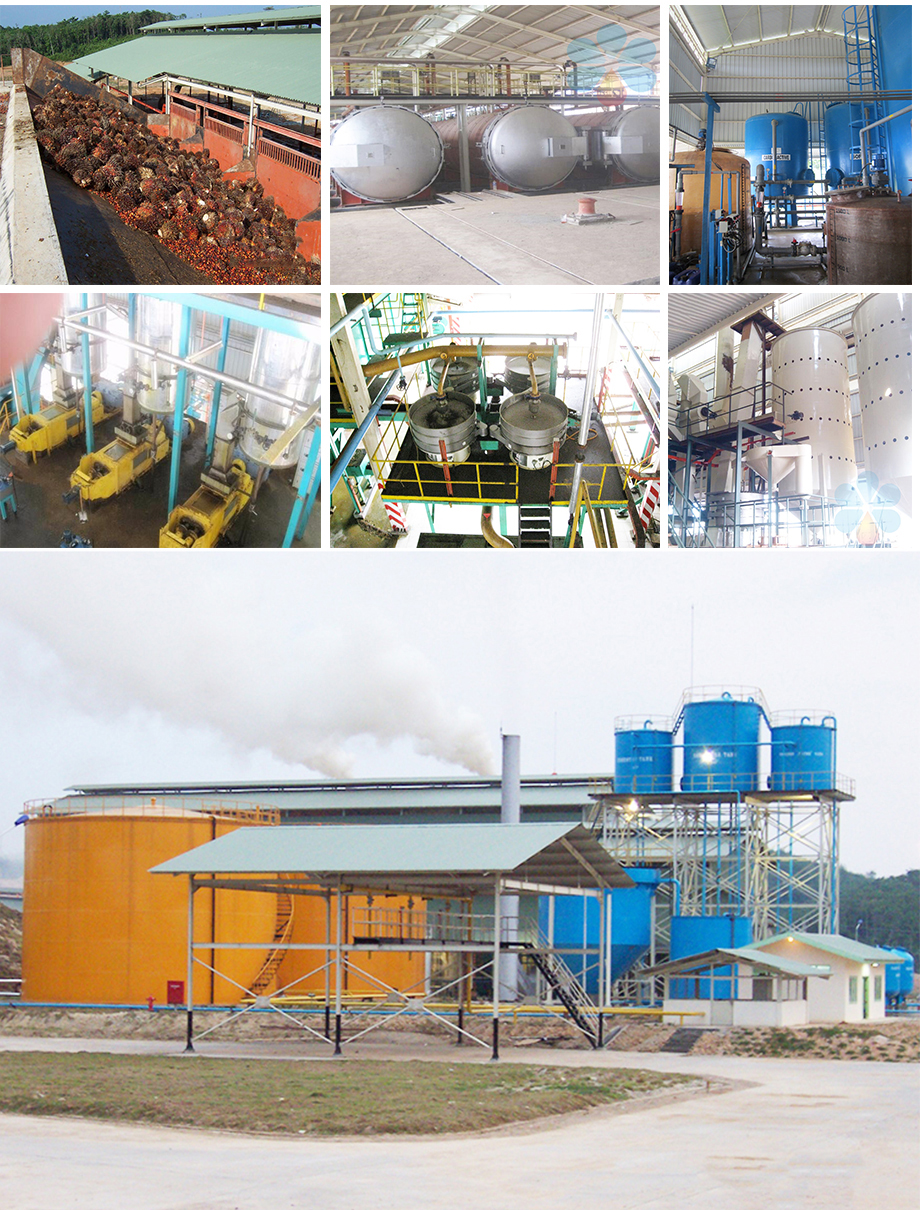

5TPH Complete palm fruit production line, palm oil production line ghana

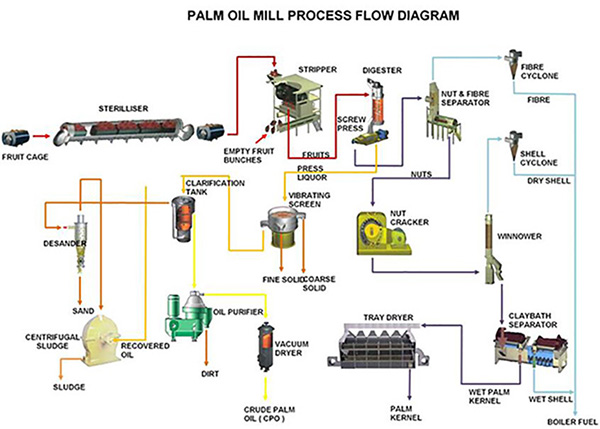

The general process : FFB(fresh palm fruit bunches)---Raw materail Reception--- Sterilizing ---Threshing ---Digesting &pressing ---Oil clarification station---Kernel recovery statation --CPO(crude palm oil)

Palm oil press line, Palm Fruit Oil Mill Press Machine Plant

Fresh palm fruit bunches are 100% of the total amount of palm fruit bunches, the proportion of empty bunches (23%), 65% of palm fruit), and the proportion of palm oil content of the whole palm bunches (26%) palm kernel oil Content (3.25) (Related Information: Palm Oil Milling Machine, Oil Palm Processing Plant Nigeria>>)

1. Palm fruit cooking pot: Put the palm skewers into a cooking pot, and cook at high temperature to destroy the lipase in the pulp to prevent the free fatty acid content in the oil from rising. On the other hand, high temperature sterilization can make the fruit soft and easy for mechanical threshing

2. Palm fruit threshing machine:Separation of oil palm fruit from fruit bunches

3. palm fruit masher:After the palm fruit bunches are mashed, the pulp and the core are separated, and the cell structure of the pulp is destroyed, which is more conducive to pressing.

4. palm fruit press:The crushed palm fruit enters the palm oil double-screw oil press for pressing. After pressing, two parts are obtained: a mixture of oil, water, solid impurities, and a pressed cake (a mixture of fibers and cores). The mixture of oil, water and solid impurities flows into the oil clarification section through the crude oil tank; the pressed cake enters the palm kernel recovery section.(Related product: Palm Oil Production Line )

5. Oil residue separation equipment:Mainly separated by high-speed centrifugal force

6. Plate and frame filter:Filtered through a layer of filter cloth, the filtered oil is more pure

7. Fiber and Palm Kernel Separation Equipment:separate fibers and palm kernels

8. palm huller:Completely separate shells and nuts,Reduce breakage rate

9. palm kernel oil press:high oil yield

1 hour 1 ton palm fruit oil press palm oil production line for sale

Hydraulic palm oil press

Separate the pulp and nut, get CPO and nut, press machine adopts the double screw hydraulic continuous discharging, greatly improving production efficiency.

Function of Palm oil clarifier

Separate the oil and the sludge (get 90% pure oil), the oil contains 45% -55% water, sludge and other things.

Function of Sterilizer

Cook the fruit bunches with high temperature and sterilization (145 ℃, 90-120minutes), easy to separate fruit from bunches, fruit becoming soft, increasing the humidity of the fruit, it is easy to extract the oil and also make the separation of the core-shell easier, preventing enzymatic decomposition to avoid free fatty acids content rising.

After Sales Service

Installation and Maintance

1. Guarantee to provide complete sets of equipment and accessories on time.

2. To ensure that the installation and commissioning of qualified inspection in one time.

3. Guaranteed to provide users with high-quality materials and preferential prices.

4. The new products and processes we have developed will be given priority to our customers.

5. The free training operation technicians to ensure that the trainers can operate independently.

6. During the installation process, we will appoint an installation supervisor on site.

7. We will appoint an experienced project manager to organize a full-scale technical installation team to perform on-site installation and commissioning.

8. After the equipment is assembled and installed on site, we will be responsible for the single-machine commissioning, on-line commissioning, and commissioning of the equipment to ensure normal operation of the equipment under full load conditions. We will provide various materials and records as required by the invitation to bid. Within one month after acceptance, we will provide customers with qualified completion files according to relevant customer requirements.

Our after sales Services & Strength

Our company always put the interests of customers and product quality to the first place, and always adhere to the "no best, only better" as our purpose. We will be commitment to provide high quality products with perfect site services and after-sale service. Now the specific commitments are as follows: 1、Ensure to timely provide complete sets of equipment and accessories. 2、Ensure that one-time installation debugging acceptance. 3、To provide high quality material with preferential price. 4、Priority to provide customer our new craftworks and products. 5、Free training technological operator to ensure the trained staff can operation independently. 6、In the installation process, we will appoint an installation supervision staff on the spot. 7、We will offer an experienced project manager, organize a good installation team for the work of field installation debugging. 8、After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, online debugging and Feeding trial operation, to ensure that equipment can normal operate in full load conditions. We will provide all kinds of information and records according to the requirements of the bid. The qualified completion files will be provided to customers according to their requirements within one month after acceptance.