100 TPD Palm Oil Processing Milling Machine in Nigeria

Weight: 1000 KG

Oil type: Palm Oil

Voltage: 380V and adjustable

Raw material: fresh palm fruit bunch, crude palm oil

Function: press palm oil

Advantage: Energy Saving

Application: Oil Production Line

Palm Oil Milling Machine

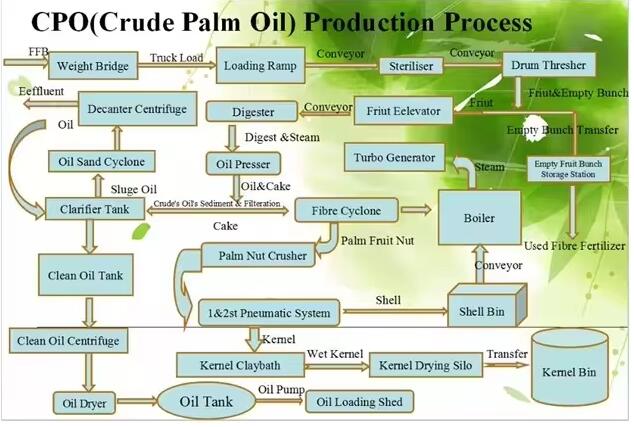

FFB Pressing Steps

1. Load FFB into sterilizing tank, inject direct steam into it for high temperature sterilization.All fruits are heated when steam passes through bunches, reduce activation of bacterium and enzyme, avoid FFA from increasing,increase crude oil quality.

2. Convey sterilized FFB to drum separator,separate EFB from FFB through rotating, EFB will be sent to pulverize for fertilizer back to orchard.

3. Thresh palm fruits through special equipment,then send them to press with twin-screw oil press, then send ,mixed liquid of sediment,water and oil to purifier,and separate crude palm oil out.

4. Solids from oil press are sent to pneumatic vertical separation column, separate fiber from nuts under wind action.

5. Fiber are conveyed to boiler for fuels.

6. Polished nuts are conveyed to nut storage vessel,then separate palm kernels after crushing.

7. Processed crude palm oil is mainly consist of solid muddy sand, water and oil.Solid parts are separated with vibration rotary screen,and crude palm oil is separated by means of statics.Heated crude palm oil is sent to vacuum dryer by oil pump to remove moisture, and stored to crude oil tank.Treated sediments discharge into sewage treatment channel,solids are used to fertilize land,steam boiler is mainly used to offer steam for generating electricity,sterilizing and heating,fuel is separated fibers and shells.

Production description:

1. FFB fresh palm fruit bunch reception

2. FFB fresh palm fruit bunch

3. FFB thresher

4. palm oil press

5. palm oil clarification

Equipment advantages:

1.High oil yield,low residual oil rate of meal

2.Low labor intensity

3.Good working environment

4.Excellent oil quality,Good meal quality.

refining working

How to Buid a Palm Kernel Oil Processing Plant in Nigeria ?

The economic benefits and importance of the oil palm tree cannot be overemphasized in today’s vegetable oil market. Some of its byproducts include palm kernel cake, palm oil, and palm kernel oil. Today we seeks to respond to the common questions that many interested entrepreneurs have in mind concerning the production of palm kernel oil. It gives you tips about investing on palm kernel oil refining in Nigeria. Some of the most commonly asked questions include:

Is starting palm kernel oil processing business worthwhile?

The production and processing of palm kernel oil offer people involves in palm oil industry an opportunity of earning a steady income. The venture also provides employment opportunities for many people who would otherwise be without jobs. On a national level, you will be contributing to the reduction of dependence on other countries as far as increasing the demand for food in Nigeria is concerned. Of utmost importance is to learn the ropes as soon as possible. You also need to give the venture deserved attention and seriousness. Since the demand for palm kernel oil is enormous locally and internationally, the business is definitely worthwhile.

Factors to consider when establishing palm kernel oil processing plant?

Before buy palm kernel oil pressing machine or refinery equipment, here are some tips for your to consider.

-

Factory Location

It is imperative that you identify a good location for your palm kernel oil refining business. To make an informed decision, consider aspects such as the availability of raw materials and your audience (the target market). Your ideal location should be in proximity to the raw materials as well as the market. At times, this might not be possible, and you may have to engage trade-offs. However, you can explore options that help you strike a balance when it comes to these two elements.

-

Startup Money: How much does it cost?

You need money for various things, including business premises, equipment, raw materials, and staff. If you have done some bit of research about this business, you already know that you need machines (for the different stages of production) to ensure faster production. Consider choosing your machines carefully to avoid unnecessary costs of repair and maintenance which can affect the profitability of your firm. If finances allow, go for high-quality equipment. Part of the capital also goes to insurance, business registration, agency fee among many others. Put into account money for paying your employees. Supposing you will be working as the manager, you will need other workers such as a technical assistant, storekeeper, production workers, quality control officer, salespeople, security officer and perhaps an administrative assistant. On average, you will need 10 members of staff, depending on the size of your business. Palm kernel oil refining business is capital intensive, and one must ensure adequate preparation. Depending on the size of the venture, you may require between N5, 000, 000 and N10, 000,000. Contact us now to know more about equipment price and investment cost!

-

When to start the business?

It is only wise to begin your palm oil extraction or refining business when everything is in place. Remember to set realistic expectations because the business is still new. Begin thinking about effective marketing strategies to spread the word about your products and in turn, attract customers. Your enthusiasm and availability of capital will determine how soon you can begin operations.