Vegetable Seeds Oil Extraction Machines, Cooking Oil Refinery Processing Plant

| Usage: | Castor, Soybean, Sesame, Peanut, Cotton Seed, Almond, Sunflower Oil |

|---|---|

| Type: | Cold & Hot Pressing Machine |

| Automatic Grade: | Automatic |

| Production Capacity: | 100TPD |

| Voltage: | 230-380-430 |

| Power(W): | 40kw/h |

Vegetable Seeds Oil Extraction Machines, Cooking Oil Refinery Processing Plant

Section 1: Oil Seeds Pre-pressing Workshop Production Line

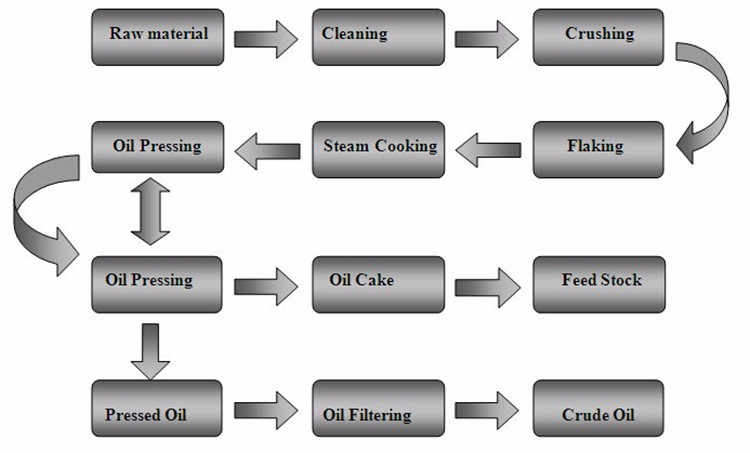

Flow chart:

1>Remove impurity process: Remove the impurities with our high efficiency vibration cleaning sieve and suction gravity stoner. the process need to be equipped with winnowing conveyor to collect the impurities.

2>Husking process: Use our sunflower seed special sheller to husk the seed and seed-sheell separator to separate the shell and kernel. The kernel will go to the next step and the shell will be transferred into the shell storage.

3>Flaking process: Use our flaking machine to flake the sunflower seed kernel.

4> Steam fry/cooking process:Turn the sunflower seeds flake into ripe after humidification, heating and steam frying.

5>Pressing process: Using oil pressing machine to press the fried sunflower seed flake.

Section 2: Oil Cake Solvent Extract Production Line:

1, the extracting device adopts stainless steel fixed grid board, frequency conversion speed regulation, extracting machine storage tank self- automatic control, high extracting efficiency, low energy consumption, extracting condenser, steam degassing condenser, stripping condenser, evaporative condenser, the final condenser are aluminum alloy tube-type condenser, the condensation effect is fast.

2, wet meal dissolution using DTC evapo-separated machine, dissolution, drying in one machine. The production of finished meal powder is fine, good color, evapo-separated machine material levels are self-control.

3, the use of film evaporation process, evaporation temperature is low, crude oil quality is good, energy saving, evapo-separated machine second times steam waste heat utilize as the first evaporator heat source.

The difference of pressing and extraction(leaching):

Squeezing method due to the yield is low, so the raw material for squeezing must be seeds of high oil content, and itself is probably oil crops; Due only to squeeze at the same time, the residual oil in the cake is high, so the modern enterprise in order to save resources, the pursuit of efficiency of cases will be to squeeze the oil cake with leaching rule of oil again.

Section 3: Oil Refining Production Line:

Some kinds of oil like sunflower, maize germ or corn oil have to waxes inside, if these impurities are not removed, the oil will freeze easily under low temperature, thus effecting oil quality and appearance. so this process is necessary in extremely cold areas.

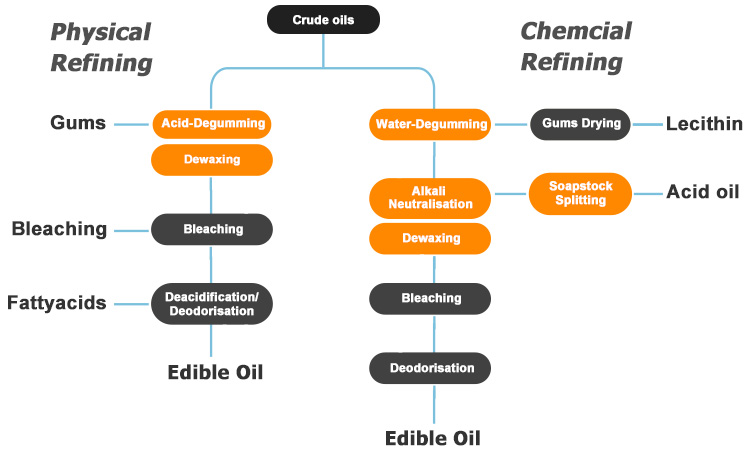

Physical Refining

In Physical Refining, Vegetable Oil is subject to distillation to remove free fatty acids. The alkali treatment is completely avoided. This reduces the amount of waste water and eliminates production of soap. This process is becoming more popular.

Chemical Refining

In Chemical Refining, Vegetable Oil is treated with caustic lye for separation of free fatty acids from oil. This is a conventional process that can be applied to all oils. A byproduct of alkali refining is soap-stock, which is used for manufacture of low quality washing soap. Alternately, the soap-stock can be treated with acid to recover fatty acids. The waste-water from refinery requires extensive treatment. This can be avoided by alternate Physical Refining process.

Oil refining plant main equipment and function:

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

Raw Material

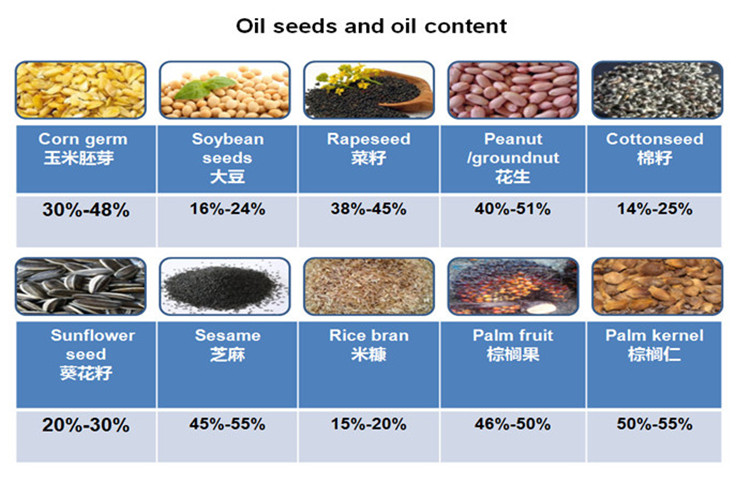

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ...

Animal raw materials: Pigs, cattle, sheep, chickens, ducks, fish, foxes, minks and other animals meat or meat residue

The raw material is: Flour,corn meal,soybean meal,maize meal,meat meal,bone meal,fish meal etc.

Fitness: about 60-80mesh which were crushed and mixed.

Moisture content: about 20%-25%.

Our Service

1. Ensure to timely provide complete sets of equipment and accessories.

2. Ensure that one-time installation debugging acceptance.

3. Free training technological operator to ensure the trained staff can independent operation.

4. In the installation process, we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

5. After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, on-line debugging and Feeding trial operation ,to ensure that equipment can normal operate in full load conditions.6. Warranty period, all because of the quality of products has caused the damage or failure of equipment, suppliers responsible for the free repair and replacing spare part.